Understanding Today’s Flat Roofing Options

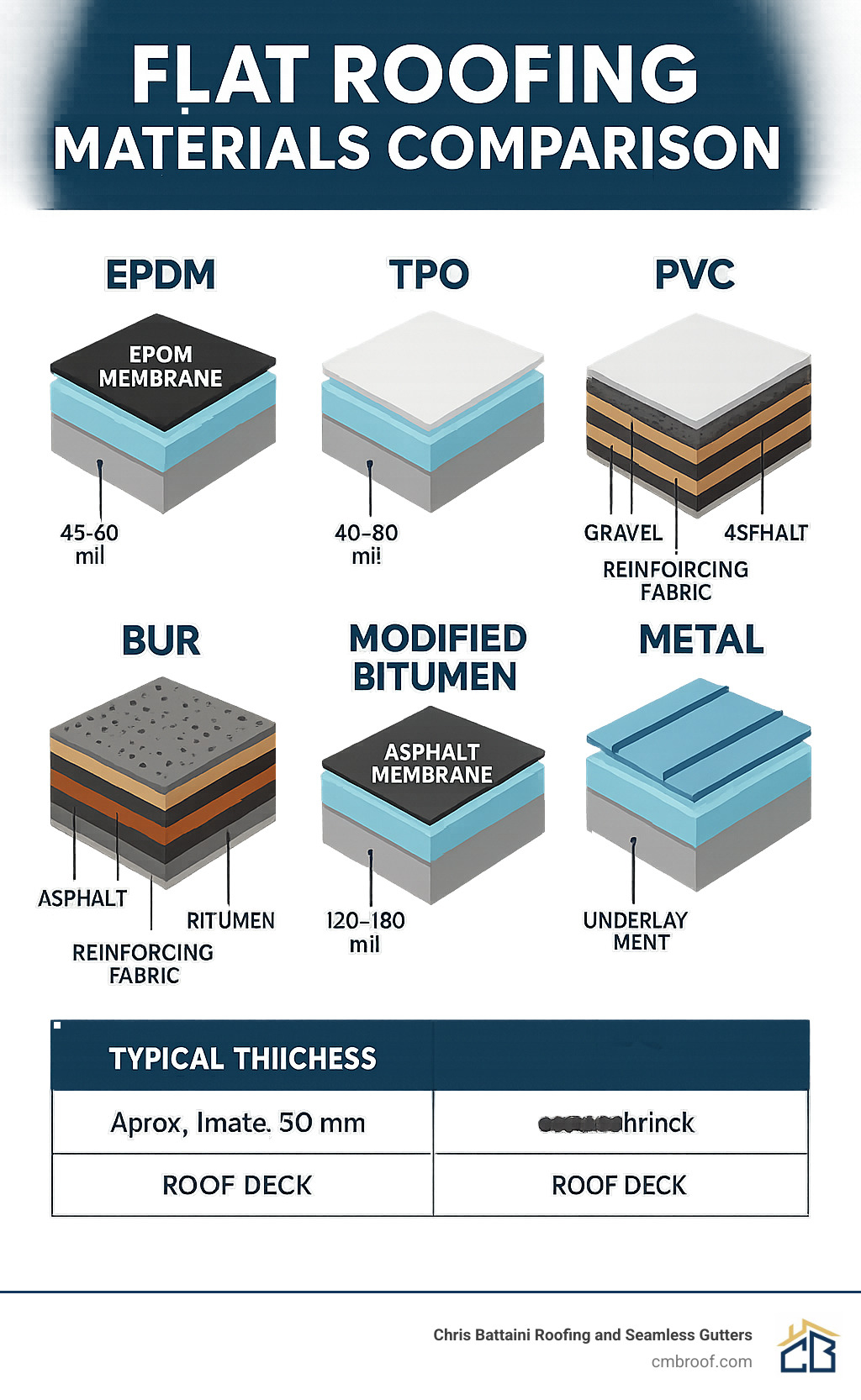

Flat roofing materials come in several high-performance options, each with distinct advantages. Here’s a quick overview of the most common types:

| Material | Lifespan | Average Cost/sq ft | Best For |

|---|---|---|---|

| EPDM Rubber | 25-50 years | $4-$13 | Durability, cold climates |

| TPO Membrane | 25-30 years | $4-$14 | Energy efficiency, hot climates |

| PVC Membrane | 25-30 years | $4-$7 | Chemical resistance, living spaces |

| Built-Up Roofing | 20-30 years | $4-$10 | Traffic resistance, traditional look |

| Modified Bitumen | 10-20 years | $4-$8 | Flexibility, moderate climates |

| Standing Seam Metal | 30-50 years | $8-$30 | Longevity, architectural appeal |

Despite their name, flat roofing materials aren’t installed on completely flat surfaces. True flat roofs actually have a slight pitch—typically between 1/4 to 1/2 inch per foot—to ensure proper drainage. This minimal slope distinguishes them from the steeper pitches of traditional residential roofing.

Flat roofs have become increasingly popular for both commercial buildings and modern residential designs. They offer practical advantages beyond their sleek appearance, including the ability to create usable outdoor space for rooftop gardens, patios, or solar panel installations.

When selecting materials for a flat roof, durability and water resistance are paramount concerns. The right choice depends on your climate, budget, building structure, and intended use of the roof space. Each material offers different benefits in terms of installation complexity, maintenance requirements, energy efficiency, and longevity.

As a homeowner or building manager facing a flat roof installation or replacement, understanding these material options is your first step toward making an informed decision that will protect your property for decades to come.

What Makes Flat Roofing Materials Unique?

Flat roofing systems stand apart from their pitched counterparts in several important ways. The minimal-slope design (typically 1/4″ to 1/2″ per foot) creates unique challenges and opportunities that influence material selection.

Unlike steeply pitched roofs that naturally shed water, flat roofs must be completely waterproof rather than just water-shedding. This fundamental difference drives the development of specialized membrane and built-up systems designed to create continuous, seamless barriers against moisture.

The urban aesthetic of flat roofs has made them increasingly popular in contemporary architecture. From sleek commercial buildings in downtown Pittsfield to modern residential designs in Bennington, flat roofs create clean lines and maximize interior space by eliminating attics. They also provide practical outdoor living space—something we’ve helped many homeowners in Berkshire County create over the years.

EPDM Rubber Membrane

When it comes to time-tested flat roofing materials, EPDM (Ethylene Propylene Diene Monomer) has earned its place as the workhorse of the industry. This synthetic rubber membrane has been sheltering buildings since the 1960s, and for good reason – it just works.

I remember installing an EPDM roof for a homeowner in North Adams about 20 years ago. Just last month, I stopped by to check on another project nearby and couldn’t resist peeking at that old garage roof. Still performing beautifully after two decades of Berkshire winters! That’s the kind of longevity (25-50 years) that makes EPDM a favorite among our practical New England customers.

You’ll typically find EPDM in classic black, though white versions are available for more energy-conscious applications. The membrane comes in thicknesses ranging from 45 to 90 mil (think the thickness of a credit card, and then some), with 60 mil being our standard recommendation for most homes and businesses. The thicker you go, the more puncture-resistant your roof becomes.

What makes EPDM shine in our Northeastern climate? Its flexibility in cold weather is best – this material stays pliable even during those bitter January mornings when everything else turns brittle. The large sheet sizes (up to 50′ × 100′) mean fewer seams where water might eventually find its way in. And its natural resistance to UV degradation keeps it performing year after year under the summer sun.

Installation options offer flexibility too. For buildings that need maximum wind resistance, we fully adhere the membrane with special bonding adhesives. When budget is a priority, ballasted systems where the EPDM is loose-laid and covered with gravel can reduce installation costs significantly. And for something in between, mechanically fastened systems secure the membrane with specialized plates and screws along the seams.

Cost-wise, EPDM sits comfortably in the middle range of flat roofing materials, with average costs between $4 and $13 per square foot installed. These figures reflect internet data averages and not actual costs for Chris Battaini Roofing and Seamless Gutters. The final price depends on factors like roof complexity, membrane thickness, and whether you choose ballasted or fully-adhered installation.

The only real drawbacks? The standard black surface absorbs heat, which might increase summer cooling costs (that’s where white EPDM comes in). And while durable, it can be punctured by sharp debris or careless foot traffic – though repairs are straightforward for professionals like us.

For more comprehensive information about flat roofing options and how EPDM compares to alternatives, visit our detailed flat roofing page.

We proudly serve Berkshire, Hampden, Hampshire, and Franklin Counties in Massachusetts.

TPO Thermoplastic Polyolefin

TPO (Thermoplastic Polyolefin) has become something of a superstar in the flat roofing materials world over the past twenty years. This single-ply membrane cleverly marries rubber’s durability with plastic’s heat-weldability—creating a roof system that’s both tough and seamless.

What immediately catches your eye with TPO is its crisp white surface. This isn’t just for looks—that white finish actively reflects sunlight and heat away from your building. One of our commercial clients in Pittsfield was genuinely surprised when their summer cooling costs dropped by about 15% after we replaced their aging black EPDM with a fresh TPO system. On hot summer days in Springfield or Holyoke, this reflective quality can make a remarkable difference in building comfort.

Beyond just saving on your electric bill, this energy efficiency often qualifies building owners for energy rebates. As building codes increasingly emphasize sustainability, a TPO roof can help you stay ahead of requirements while doing something good for both your budget and the environment.

TPO typically comes in thicknesses between 45 and 80 mils (0.045 to 0.080 inches), with 60 mil being our most common recommendation for commercial projects. With proper installation and maintenance, you can expect your TPO roof to provide reliable service for 25-30 years.

What makes TPO special? The seams. Unlike roofing systems that rely on adhesives or tapes, TPO seams are heat-welded using specialized equipment that essentially melts the edges together. This creates bonds that are actually stronger than the membrane itself—forming a truly watertight system with no weak points. When we finish a TPO installation, what you get is essentially one continuous sheet of roofing material, regardless of the actual size of your building.

TPO also offers impressive flexibility, allowing it to handle building movement and settlement without cracking. Its chemical resistance helps prevent mold growth and dirt accumulation, while quality TPO membranes provide good impact resistance against hail and other debris.

We typically install TPO in one of two ways: mechanically attached (secured to the roof deck with screws and plates along the seams) or fully adhered (bonded completely to the substrate with adhesive for maximum wind resistance). While ballasted TPO installations are possible, they’re less common in our region.

Cost-wise, TPO sits in the middle range of flat roofing materials, with average installed costs between $4 and $14 per square foot. Variables affecting price include project complexity, membrane thickness, and whether insulation needs replacement. These are average costs based on internet data and not actual costs for Chris Battaini Roofing and Seamless Gutters.

One thing we’ve learned over years of installations: TPO quality can vary between manufacturers. Some early formulations had issues with premature aging, which is why we exclusively use premium TPO products from established manufacturers with proven track records. When you choose us for a TPO installation, you’re getting materials we trust enough to put on our own buildings.

For more information about our commercial roof installation services, including TPO systems, visit our commercial roof installation page.

PVC Vinyl Membrane

When it comes to chemical resistance and durability in demanding environments, PVC (Polyvinyl Chloride) membrane truly shines among flat roofing materials. This veteran of the roofing industry has been proving its worth for decades longer than newer alternatives like TPO.

Like its thermoplastic cousin, PVC comes primarily in white and light colors that reflect sunlight rather than absorb it. This reflective quality makes summer days in Springfield or Holyoke much more bearable inside your building. One of our commercial clients reported that after we installed their PVC roof, their top-floor offices finally became comfortable in July and August without cranking the AC to maximum.

What truly sets PVC apart is its remarkable resistance to chemicals. I remember installing a PVC system for a restaurant owner in Great Barrington who was concerned about their kitchen exhaust. The grease and cooking oils would have slowly degraded other roofing types, but five years later, that PVC roof looks practically new. This chemical resistance makes PVC the go-to choice for restaurants, manufacturing facilities, and laboratories where airborne contaminants are a concern.

With a typical lifespan of 25-30 years, PVC delivers excellent long-term value. Available in thicknesses ranging from 50 to 80 mils (0.050 to 0.080 inches), the material maintains its flexibility throughout its life, even during those bitter cold Berkshire winters we all know too well.

PVC’s fire resistance is another significant advantage—it’s inherently difficult to ignite and won’t support combustion. Its heat-welded seams create bonds stronger than the membrane itself, virtually eliminating the risk of seam failure that plagued older roofing systems. The material’s flexibility prevents cracking even with building movement, and many PVC roofs can be recycled at the end of their service life.

The average installed cost for PVC ranges from $4 to $7 per square foot, though complex projects with custom details can reach significantly higher prices. These are average costs based on internet data and not actual costs for Chris Battaini Roofing and Seamless Gutters.

PVC truly excels when it comes to rooftop living spaces. Last summer, we helped a homeowner in Williamstown transform their flat garage roof into a gorgeous rooftop garden using PVC as the waterproofing foundation. The membrane’s robust nature and resistance to root penetration make it perfect beneath pavers or green roof systems.

We typically install PVC using one of three methods: fully adhered (bonded to the substrate with adhesive), mechanically attached (secured with screws and plates along the seams), or induction welded (a newer technique that fastens the membrane without penetrating it). Each approach has its place depending on your building’s specific needs.

For scientific research supporting the benefits of cool roofs like PVC, check out this research on cool roofs. The energy savings and reduced urban heat island effect provide benefits beyond just your building.

Built-Up Roofing (BUR)

When you see a commercial building with a gravel-topped roof, you’re likely looking at Built-Up Roofing (BUR) – affectionately known as “tar and gravel” roofing. It’s the grandfather of flat roofing materials, with a history stretching back more than a century, and it’s still going strong today.

Unlike single-layer systems, BUR is exactly what its name suggests – built up on-site through multiple layers of bitumen (asphalt or coal tar) alternating with reinforcing fabrics called felts or “plies.” Think of it as making a roofing lasagna, with each layer adding strength and protection. Most systems include three to five plies, topped with gravel, mineral granules, or a reflective coating for added protection.

I remember a commercial project we completed in downtown Pittsfield where the owner was replacing a BUR roof that had faithfully served for nearly 25 years. That kind of longevity isn’t unusual – with proper installation and regular maintenance, these systems typically last 20-30 years, with each layer contributing about 5 years of life.

What makes BUR stand out is its multi-layer redundancy. If one layer gets damaged, you’ve got several backup layers still protecting your building. This self-healing characteristic is particularly notable with coal tar versions (though these are less common now due to environmental concerns) – on warm days, minor cracks can actually seal themselves as the material softens slightly.

The absence of large seams is another significant advantage. While single-ply systems have seams that can potentially fail, BUR creates a continuous surface across your entire roof. This seamless quality, combined with the gravel top layer, makes BUR exceptionally resistant to punctures and foot traffic – perfect for roofs that need regular maintenance access.

Of course, BUR isn’t without its challenges. At 5-6 pounds per square foot (or more with gravel), it’s significantly heavier than membrane options. Before recommending BUR, we always ensure your building’s structure can handle this additional weight. The installation process also involves hot asphalt, which creates distinctive odors during application – something to consider if your building will remain occupied during installation.

Cost-wise, BUR sits in the middle range of flat roofing materials, with average installed costs between $4 and $10 per square foot, depending on the number of plies, surfacing type, and project complexity. These are average costs based on internet data and not actual costs for Chris Battaini Roofing and Seamless Gutters.

The installation process is something of an art form that we’ve perfected over decades:

- We start by preparing the roof deck and installing base sheets if needed

- Then comes the hot bitumen application, followed by carefully embedded reinforcing felts

- We repeat these layers until reaching the specified number of plies

- A final flood coat of bitumen creates a seamless surface

- Finally, we add the protective top layer – typically gravel for maximum durability

That gravel top isn’t just decorative – it shields the bitumen from UV damage, provides fire resistance, and adds weight to prevent wind uplift. For more energy-efficient applications, especially in warmer areas like Springfield, we might recommend a reflective coating instead of traditional gravel.

For more details about our roof installation services, including BUR systems, visit our roof installation page.

Modified Bitumen

If traditional built-up roofing and modern single-ply membranes had a child, it would be Modified Bitumen. This innovative flat roofing material emerged in the 1960s as roofing technology’s answer to “can we make asphalt better?” – and the answer was a resounding yes.

Modified Bitumen takes conventional asphalt and improves it with polymers, creating a material that brings the best of both worlds to your roof. There are two main types you’ll encounter:

SBS (Styrene-Butadiene-Styrene) modified membranes feel rubber-like and offer remarkable flexibility. We often recommend these for our Berkshire County clients because they handle our cold New England winters beautifully, stretching and returning to shape without cracking during freeze-thaw cycles.

APP (Atactic Polypropylene) modified membranes have a more plastic-like quality, standing up exceptionally well to intense UV exposure and high temperatures. They’re less common in our region but excellent in areas with extreme summer heat.

I remember a project we completed for a historic building in downtown Great Barrington. The owner wanted modern protection without disrupting the building’s traditional character. Modified bitumen was the perfect solution – it provided contemporary performance while visually complementing the neighboring structures. Five years later, it’s still performing flawlessly through our Berkshire seasonal extremes.

Modified Bitumen typically gives you 10-20 years of reliable service, positioning it between single-ply membranes and traditional BUR systems for longevity. The material comes in rolls with factory-controlled thickness (usually 160-180 mils), making it substantially thicker than single-ply options.

What makes Modified Bitumen particularly suited to our New England climate is its exceptional flexibility during temperature swings. When winter hits and most materials become brittle, SBS-modified membranes remain pliable and resist cracking. The reinforcement mats (typically fiberglass or polyester) provide excellent tear resistance, while the two-layer installation (base sheet plus cap sheet) creates built-in redundancy for added protection.

Installation methods have evolved significantly over the years, giving property owners several options:

Torch-applied systems use a propane torch to heat the backing and create a bond. While effective, this method requires specialized safety precautions and isn’t ideal for all situations due to fire hazards.

Self-adhered (peel-and-stick) systems have become increasingly popular, especially for residential applications. As one client in Pittsfield joked, “It’s like putting a giant sticker on your roof!” These systems eliminate fire risks and unpleasant odors during installation.

Cold-applied systems use special adhesives instead of heat, reducing fire risk while maintaining excellent performance.

Hot-mopped applications use hot asphalt similar to traditional BUR installation methods.

Cost-wise, Modified Bitumen strikes a middle ground among flat roofing materials, with average installed costs ranging from $4 to $8 per square foot. More complex projects with multiple layers or challenging details can run higher. These are average costs based on internet data and not actual costs for Chris Battaini Roofing and Seamless Gutters.

While Modified Bitumen offers many advantages, it does have some considerations to keep in mind. It’s heavier than single-ply options (though lighter than traditional BUR), and torch-down application presents fire hazards during installation. That’s why we often recommend self-adhered or cold-applied systems for residential projects.

For clients concerned about condensation issues in flat roofing systems, we recommend reviewing this scientific research on condensation, which offers valuable insights into proper ventilation and insulation strategies.

Standing Seam Metal

Standing Seam Metal roofing sits proudly at the premium end of flat roofing materials, offering exceptional longevity and striking visual appeal. You might typically associate metal roofing with sloped applications, but today’s specially engineered standing seam systems perform beautifully on low-slope roofs with pitches as minimal as 1/4″ per foot.

What makes these systems special are their continuous metal panels that run uninterrupted from ridge to eave, connected by raised seams that stand above the water-carrying surface. This clever design dramatically reduces leak potential by elevating the vulnerable connections away from where water flows.

“The standing seam system we installed on a contemporary home in Williamstown not only created a stunning visual statement but also gave our client confidence their roof would outlast most other components of their home,” notes Chris Battaini. “The clean lines perfectly complemented their modern architecture while ensuring decades of worry-free performance.”

These sophisticated roofing systems can be crafted from several metal options, each with distinct advantages. Galvanized or Galvalume steel provides the most economical choice, while aluminum offers superior corrosion resistance—ideal for properties closer to the coast. For those seeking true luxury, copper creates a distinctive appearance that develops a beautiful natural patina over time, while zinc provides self-healing properties and remarkable longevity.

With proper installation, standing seam metal roofs typically last 30-50 years—outperforming every other flat roofing material on the market. This exceptional durability stems from quality metals combined with intelligent design features like concealed fasteners and clips that accommodate thermal movement.

Beyond their impressive lifespan, standing seam systems offer numerous practical benefits. Their excellent weather resistance handles everything from Berkshire County’s heavy snow loads to strong winds with ease. Many feature reflective coatings that significantly reduce summer cooling costs. Environmentally conscious property owners appreciate that most metal roofing contains recycled content and remains 100% recyclable at the end of its service life.

Metal roofs also provide the perfect foundation for solar panel installation without requiring roof penetrations, making them increasingly popular among forward-thinking homeowners planning for future energy independence. And with dozens of factory-applied finishes available (typically carrying 30+ year warranties against fading), you can dramatically transform your building’s appearance while ensuring decades of protection.

This premium performance does come with higher upfront costs. Average installed prices range from $8 to $30 per square foot, depending on metal type, panel design, and project complexity. These are average costs based on internet data and not actual costs for Chris Battaini Roofing and Seamless Gutters.

Installing standing seam metal on low-slope applications requires specialized expertise that goes beyond standard roofing knowledge. The process begins with a properly prepared substrate and high-temperature self-adhering membrane. Panels are then precisely joined using mechanical seaming tools that crimp the metal together, creating watertight connections. Special clips allow natural expansion and contraction without stressing the metal, while carefully designed flashings and transitions maintain water-tightness throughout the system.

For more detailed information about our expert metal roofing installation services, visit our metal roofing installation page.

Cost & Lifespan at a Glance

When you’re weighing your options for a new flat roof, two factors typically drive the decision more than any others: how much it costs now, and how long it’ll last. I’ve seen this play out countless times with homeowners across Berkshire County – the initial sticker shock versus the promise of decades of protection.

Let’s break down what you can realistically expect from each flat roofing material:

| Material | Average Cost/sq ft | High-End Cost/sq ft | Typical Lifespan | Warranty Period | Maintenance Level |

|---|---|---|---|---|---|

| EPDM Rubber | $4-$13 | $15-$39 | 25-50 years | 20-30 years | Low |

| TPO Membrane | $4-$14 | $16-$42 | 25-30 years | 15-30 years | Low |

| PVC Membrane | $4-$7 | $12-$21 | 25-30 years | 15-30 years | Low |

| Built-Up Roofing | $4-$10 | $12-$30 | 20-30 years | 10-20 years | Moderate |

| Modified Bitumen | $4-$8 | $12-$24 | 10-20 years | 10-20 years | Moderate |

| Standing Seam Metal | $8-$30 | $24-$90 | 30-50 years | 30-50 years | Very Low |

Note: These are average costs based on internet data and not actual costs for Chris Battaini Roofing and Seamless Gutters. High-end costs may apply to complex installations, premium materials, or challenging access conditions.

Looking beyond the upfront price tag is crucial when making this investment. I often tell clients in Pittsfield and Great Barrington to think about the “cost per year” rather than just the installation price. For example, that standing seam metal roof might seem expensive today, but when you divide its cost over its incredible 50-year potential lifespan, it can actually work out cheaper than replacing a budget-friendly modified bitumen roof every 15 years.

The maintenance factor also plays into this equation. EPDM, TPO, and PVC systems typically need just occasional inspections and minor repairs. In contrast, built-up roofing and modified bitumen might require more frequent attention, especially around flashings and seams. Standing seam metal often needs virtually no maintenance beyond gutter cleaning – a huge plus for busy property owners.

Warranty coverage varies significantly too. Most manufacturer warranties only cover the materials themselves, while contractor warranties address the quality of installation. That’s why we at Chris Battaini Roofing take such pride in our workmanship guarantees – they complement the manufacturer’s material coverage to give you comprehensive protection.

I’ve seen this value equation play out with a commercial client in Williamstown who initially balked at upgrading from modified bitumen to a premium EPDM system. Seven years later, while their neighbors were already dealing with roof issues, their building remained perfectly protected – proving that sometimes, spending a bit more upfront truly pays dividends down the road.

When comparing these options for your property, the perfect balance of cost and longevity depends on your specific situation – your building’s architecture, your local climate conditions, and how long you plan to own the property all factor into making the smartest choice.

Installation & Maintenance Essentials

The secret to making your flat roofing materials last isn’t just in what you choose—it’s how it’s installed and cared for afterward. Even top-tier materials can fail early if they’re poorly installed or neglected.

We’ve seen this throughout Berkshire County—a well-maintained EPDM roof often outlasts a neglected PVC system, despite the latter’s technical advantages. That’s why we recommend a consistent maintenance routine for all our clients: schedule professional inspections twice yearly (spring and fall), plus after any major storms. These check-ups catch small issues before they become expensive problems.

Ponding water is perhaps the biggest enemy of any flat roof. Even materials designed to handle standing water will eventually suffer if pools remain for more than 48 hours. Keep your drains and scuppers clear of leaves and debris, especially during fall when gutters tend to clog. A simple monthly visual inspection from the ground can spot potential drainage issues early.

Flashings deserve special attention during maintenance visits. These transition areas around vents, edges, and equipment mounts are common failure points. When we inspect roofs in places like Pittsfield or North Adams, we often find that the membrane itself is perfect, but water has worked its way in through compromised flashings.

When planning your flat roof installation, you’ll face an important design decision between “warm roof” and “cold roof” construction:

For our New England climate, we typically recommend the “warm roof” approach, where insulation sits above the structural deck but below the waterproofing layer. This design prevents condensation issues that commonly plague cold roofs in our freeze-thaw cycles. A client in Williamstown who opted for this configuration reported significantly improved energy efficiency and eliminated the winter condensation problems they’d experienced with their previous roof.

The DIY question comes up often, especially with homeowners looking to save on their garage or shed roof. While materials like peel-and-stick modified bitumen seem DIY-friendly, we’ve unfortunately seen too many failed attempts. A Pittsfield homeowner tried installing EPDM himself last year, only to find water pooling in poorly adhered sections after the first rain. The eventual replacement cost far exceeded what professional installation would have been.

Beyond the technical challenges, most manufacturer warranties become void without professional installation. When you consider that a quality flat roof represents a significant investment, the peace of mind from proper installation and valid warranty protection usually outweighs potential DIY savings.

For those interested in creating usable outdoor space, flat roofing materials like PVC and TPO provide excellent foundations for rooftop patios and gardens. These systems can be designed with additional protection layers to accommodate pavers, decking, or even intensive green roof installations. A Great Barrington client transformed their downtown commercial building’s roof into a stunning employee lounge space, complete with container gardens and seating areas—all possible because they chose the right material and installation method.

Sustainability considerations continue to grow in importance for our clients. Beyond the energy efficiency of reflective membranes, many flat roofing materials now incorporate recycled content or offer end-of-life recycling options. TPO and PVC manufacturers often run take-back programs, while metal roofing is nearly 100% recyclable. Even traditional materials like modified bitumen have evolved to include more environmentally friendly installation methods that eliminate VOCs and open flames.

Your warranty coverage deserves careful attention too. Manufacturer warranties typically cover materials for 10-30 years depending on the product, but most exclude labor costs for replacement if problems occur. At Chris Battaini Roofing and Seamless Gutters, our workmanship warranties complement these material guarantees to provide comprehensive protection for our clients throughout the roof’s expected lifespan.

For more detailed information about our professional approach to commercial roofing installation and maintenance, visit our commercial roofing page.

Comparing Flat Roofing Materials for Your Climate

The Berkshires and Southern Vermont present unique climate challenges that directly impact how flat roofing materials perform. Our region’s dramatic seasonal shifts require thoughtful material selection.

Snow load concerns are paramount in our area, where winter accumulations can place tremendous weight on flat surfaces. EPDM, TPO, and standing seam metal handle these loads admirably, with metal offering the added benefit of shedding snow more readily due to its slick surface. During the heavy snows of 2021, we observed how buildings with metal roofing cleared naturally days faster than those with membrane systems.

The UV exposure in our region, while less intense than southern states, still takes a toll on roofing materials. White or light-colored membranes like TPO and PVC reflect these rays, protecting the roof structure and reducing summer cooling demands. A business owner in Pittsfield switched from black EPDM to white TPO during a recent replacement and reported a noticeable difference in upper-floor comfort during July and August.

Wind uplift becomes a significant factor in our higher elevations and during the intense storms that occasionally sweep through the region. Fully-adhered systems generally provide better wind resistance than mechanically-fastened options, while standing seam metal offers excellent performance due to its interlocking panel design. After a particularly violent windstorm last year, we noticed that buildings with fully-adhered systems experienced significantly fewer issues than those with alternative attachment methods.

Massachusetts has adopted progressive energy codes that may influence your roofing choice. Reflective “cool roof” materials can help meet these requirements and might qualify for utility company rebates. One of our Springfield clients received a substantial energy rebate after installing a highly reflective TPO system that exceeded code requirements for solar reflectance.

If you’re considering a green roof installation, your waterproofing layer must resist root penetration. PVC and TPO membranes excel in these applications, while EPDM typically requires additional root barriers. A local architect we work with specifically specifies PVC for all his living roof designs due to its superior resistance to plant roots and fertilizer chemicals.

End-of-life recycling options vary significantly between materials. Metal roofing leads in sustainability, being nearly 100% recyclable. Some PVC and TPO manufacturers now offer take-back programs, while EPDM recycling, though improving, remains limited in our region. These considerations matter increasingly to our environmentally conscious clients throughout Western Massachusetts.

How to Choose the Best Flat Roofing Materials for Your Budget

Finding the perfect balance between upfront costs and long-term performance is the key to smart flat roofing materials selection. We guide our clients through this decision with a focus on their specific needs rather than pushing the most expensive option.

Your building’s purpose should drive material selection. The roof protecting your family’s living space deserves different considerations than one covering an unheated storage building. For homes and occupied spaces, energy-efficient membranes like TPO or PVC often provide the best comfort and performance. For utility buildings, economical EPDM might be perfectly adequate. Restaurants or industrial facilities with chemical exposure typically need the chemical resistance of PVC. Historic buildings in towns like Lenox or Stockbridge often benefit from modified bitumen’s traditional appearance that complements their architectural heritage.

Consider your ownership timeframe when making this investment. If you’re planning to sell in a few years, you might prioritize different aspects than someone settling in for decades. A business owner in North Adams opted for standing seam metal despite its higher initial cost because, as he put it, “I’m tired of replacing roofs—I want this to be the last one I ever install.” The premium materials often deliver better lifetime value for long-term owners.

Local building codes in Massachusetts and Vermont can sometimes narrow your options. Some municipalities have specific requirements for fire ratings, energy efficiency, or wind resistance. We stay current with these regulations across all the communities we serve, ensuring your new roof will meet or exceed all local standards.

Think ahead to potential future additions. If you might add solar panels, a rooftop deck, or a green roof system in the coming years, choose a material that accommodates these improvements without requiring replacement. A forward-thinking client in Williamstown selected PVC specifically because it would allow for a rooftop patio installation the following summer.

When we provide quotes, we break down costs for different material options while highlighting the expected lifespan and maintenance requirements of each. This transparent approach helps you make truly informed comparisons beyond just the initial price tag. A recent client in Great Barrington was initially attracted to modified bitumen’s lower cost but ultimately chose TPO after we demonstrated that its longer lifespan and energy savings would offset the higher initial investment within seven years.

A comprehensive roof budget should include more than just the membrane itself. Factor in the removal and disposal of existing materials, potential deck repairs, insulation upgrades to meet current energy codes, flashing replacements, and drainage improvements. These elements significantly impact both the performance and total cost of your roofing project.

By carefully weighing these factors against your specific needs and budget constraints, you’ll arrive at a roofing solution that delivers the best possible value for your situation—whether that’s a premium PVC system for your family home or a practical EPDM membrane for your workshop.

We proudly serve Berkshire, Hampden, Hampshire, and Franklin Counties in Massachusetts.

Frequently Asked Questions about Flat Roofing

Can I install shingles on a flat roof?

We hear this question all the time, and I have to be straightforward with you—traditional asphalt shingles and flat roofs simply don’t mix. Here’s why: shingles are designed for steeper slopes (4:12 or greater) where they can effectively shed water downward through overlapping layers.

On your flat roof with its minimal pitch (usually just 1/4″ to 1/2″ per foot), rainwater would stubbornly sit there and eventually find its way under those shingles, creating leaks and headaches for you. Flat roofs need continuous waterproof barriers, not water-shedding materials.

“But what about those special low-slope shingles I’ve heard about?” Yes, some manufacturers do make products rated for slopes as low as 2:12, but even these aren’t suitable for truly flat roofs. For those in-between slopes (2:12 to 4:12), you’d need special installation techniques and ice and water shield underlayment throughout.

Your best bet for a flat roof is to stick with materials designed specifically for the job: flat roofing materials like EPDM rubber, TPO, PVC membranes, modified bitumen, built-up roofing (BUR), or standing seam metal. These systems are engineered from the ground up to provide waterproof protection, not just shed water.

If you’re interested in learning more about where shingles do work well, check out our roof shingles page.

What are the most common problems with flat roofs and how do I prevent them?

Having installed and repaired hundreds of flat roofs throughout Berkshire County, we’ve seen the same issues pop up time and again. The good news? With the right approach, most are preventable.

Ponding water tops our problem list. When water sticks around on your roof for more than 48 hours after rain, it’s not just unsightly—it’s actively degrading your roofing materials. Last year, we helped a client in Adams whose flat garage roof had developed shallow pools after every rainstorm. By adding tapered insulation to create proper drainage pathways, we solved the issue before it led to leaks.

Seam failures are another common culprit, especially with single-ply membranes. Those seams are potential weak points where water can eventually find its way in. This is one reason we prefer heat-welded seams (for TPO and PVC) whenever possible—they create bonds stronger than the membrane itself.

Punctures and tears happen more often than you’d think. Just one dropped tool from an HVAC technician can compromise your roof’s integrity. We always recommend installing walkway pads in high-traffic areas and being selective about who gets roof access.

Flashing failures around edges, walls, and penetrations account for a huge percentage of the leaks we repair. Proper flashing installation is truly an art form, requiring precise measurements and careful termination details.

Improper repairs often make small problems worse. We recently inspected a roof in Pittsfield where the owner had attempted repairs with hardware store caulk—which was incompatible with their EPDM membrane and actually accelerated the deterioration. Professional repairs using the right materials would have cost less in the long run.

Should flat roof installation be DIY or left to professionals?

I understand the appeal of DIY projects—I’m a hands-on person myself. But after 20+ years in this business, I’ve seen too many flat roof DIY attempts end in costly failures.

Here’s the reality: professional roofers bring specialized skills that only come from installing hundreds of roof systems. When one of our crews heat-welds a TPO seam, they’re drawing on years of experience to create that perfect bond. When they flash a complex roof penetration, they’re applying techniques refined over countless installations.

Safety is another major concern. Even “flat” roofs present fall hazards, and some installation methods (like torch-down modified bitumen) involve open flames. Our crews use proper safety equipment and follow established protocols to mitigate these risks.

The tool investment for proper installation can be substantial. A quality heat welder for TPO or PVC seams costs thousands of dollars—a big expense for a one-time project. And those specialized tools require skilled hands to use properly.

Perhaps most importantly, warranty protection typically depends on professional installation. A client in Williamstown learned this lesson the hard way when their DIY EPDM roof leaked after just two years. Not only did they face the cost of a complete replacement, but they finded their material warranty was invalid because they hadn’t used a certified installer.

That said, there are ways homeowners can participate in roof maintenance. Performing regular visual inspections, clearing debris from drains, and promptly reporting potential issues are valuable contributions to your roof’s longevity.

For a system that protects your entire building investment, professional installation provides peace of mind that simply can’t be matched. When our owner Chris Battaini personally oversees your roofing project, you’re getting decades of expertise applied to every detail of your roof system.

We proudly serve Berkshire, Hampden, Hampshire, and Franklin Counties in Massachusetts.

Conclusion

After exploring the landscape of flat roofing materials, you’ve now got the knowledge to make an informed choice that will protect your property for decades to come. Each material we’ve examined brings something special to the table, like old friends with different strengths.

EPDM shines in our New England winters, flexing without complaint when temperatures plummet. I’ve seen 30-year-old EPDM roofs still performing beautifully across Berkshire County, quietly doing their job through countless freeze-thaw cycles.

TPO and PVC are the energy-efficient cousins in the family, reflecting summer heat and potentially trimming your cooling bills. Those heat-welded seams create bonds stronger than the material itself—a huge advantage over older roofing technologies. PVC brings that extra chemical resistance that makes it perfect for restaurants and industrial buildings.

Built-Up Roofing is like that reliable old friend who’s been around forever. There’s something reassuring about those multiple layers of protection, each one backing up the others if trouble strikes.

Modified Bitumen blends traditional looks with modern performance—perfect when you want reliability without reinventing the wheel. The peel-and-stick versions have made installation cleaner and safer than ever.

Standing Seam Metal is the premium choice that makes a statement while potentially outlasting everything else. Yes, it costs more upfront, but that gleaming metal roof might be the last one your building ever needs.

Your perfect match depends on several factors unique to your situation—your building’s design, your local climate (which we know well in Massachusetts and Vermont), your budget constraints, and how you plan to use the roof space. Do you need a simple waterproof barrier, or are you dreaming of a rooftop garden retreat?

At Chris Battaini Roofing and Seamless Gutters, we take pride in guiding you through these choices with honest, experienced advice. What makes us different is that when you work with us, you’re dealing directly with the owner and experienced professionals—not salespeople or subcontractors. We’re on-site, hands-on, and personally invested in your satisfaction.

Whether you’re replacing an aging system or planning something new, the right material is only half the equation—expert installation is equally crucial. A premium material poorly installed will fail, while even mid-range materials can perform exceptionally when installed with skill and care.

The decisions you make today will protect your property through rain, snow, sun, and wind for decades. We’ve helped countless property owners throughout Berkshire County and Southern Vermont steer these choices, and we’re ready to do the same for you.

For more detailed information or to discuss your specific project, visit our flat roofing solutions page or reach out for a consultation. Let’s work together to find the perfect flat roofing materials for your unique needs.

We proudly serve Berkshire, Hampden, Hampshire, and Franklin Counties in Massachusetts.