Why Installing Metal Roof Over Shingles on Shed Makes Perfect Sense

Installing metal roof over shingles on shed projects save time and money, giving your storage building a durable upgrade that lasts for decades. Instead of a messy tear-off, you can install metal panels directly over your existing roof, as long as it’s done correctly and the old roof is in decent shape.

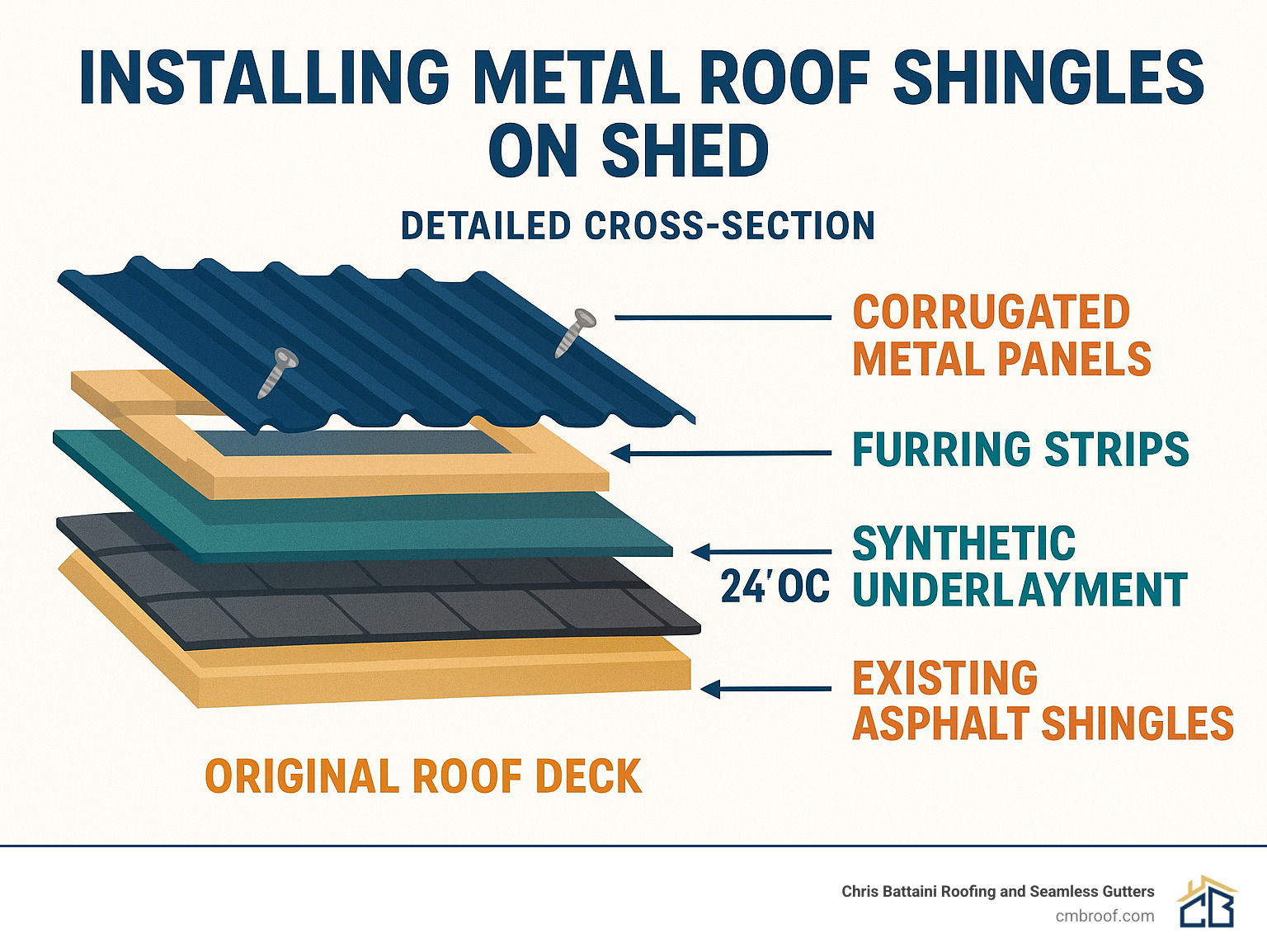

Quick Answer for Installing Metal Roof Over Shingles on Shed:

- Inspect existing shingles – Must be flat, secure, and not curling

- Install furring strips – 1×4 boards spaced 24″ on center over shingles

- Add synthetic underlayment – Creates moisture barrier and smooth surface

- Attach metal panels – Screw through metal into furring strips, not shingles

- Install trim and flashing – Seal edges and ridge for weatherproofing

This overlay method is ideal for sheds, which are typically unheated and have simpler roof lines. The key is proper preparation, especially the use of furring strips. These strips create a vital air gap that prevents moisture issues, protects the metal from abrasion, and provides a solid fastening surface.

With a lifespan of 50+ years compared to 15-25 for shingles, a metal roof is a worthwhile investment for any shed.

Installing metal roof over shingles on shed terms simplified:

Why Choose a Metal Roof-Over for Your Shed?

When your shed’s roof ages, you can either tear it off or install a new metal roof over the existing shingles. The latter, installing metal roof over shingles on shed, is a popular, practical choice that avoids a messy tear-off while adding an extra layer of protection.

The Pros: A Smart Upgrade

The benefits of a metal roof overlay make it a smart choice for most homeowners.

- Longevity: A metal roof can last 50+ years, far outliving asphalt shingles (15-25 years). It’s a long-term solution you may only have to install once.

- Cost-effectiveness: By skipping the tear-off, you avoid significant labor and disposal fees, making the project more affordable.

- Time savings: An overlay is much faster and less disruptive than a full replacement, getting your shed back in service quickly.

- Lightweight material: Metal roofing is surprisingly light and won’t over-stress most shed structures.

- Increased durability: Metal offers superior fire resistance and insect resistance, and it won’t rot, keeping your shed and its contents safer.

For more details about our comprehensive roofing solutions, check out our Roof Installation services.

The Cons and Risks to Consider

It’s important to be aware of the potential downsides before deciding on an overlay.

- Potential for trapped moisture: Without proper ventilation (like an air gap from furring strips), moisture can get trapped between the layers, leading to condensation and mold. Proper ventilation is critical.

- Hiding underlying deck damage: An overlay prevents a full inspection of the roof deck. Pre-existing rot or soft spots might be missed if not carefully checked beforehand.

- Added weight concerns: Though metal is light, the combined weight of two roofs should be considered, especially for older or poorly framed sheds. Learn more about the importance of structural integrity.

- Thermal expansion abrasion: Metal expands and contracts with temperature. If it rubs directly against rough shingles, the protective coating can be damaged. Furring strips are essential to prevent this.

- Building code limitations: Some municipalities have rules against more than two roof layers. Always check local codes before starting.

Here’s how the two approaches stack up:

| Factor | Full Tear-Off & Replacement | Installing Metal Roof Over Shingles (Overlay) |

|---|---|---|

| Cost | Higher due to labor and disposal fees | Lower, avoiding tear-off and disposal costs |

| Labor Time | Longer, tear-off is time-consuming | Shorter, faster installation process |

| Disposal | Significant waste, landfill fees required | Minimal waste, more environmentally friendly |

| Structural Inspection | Complete deck inspection possible | Limited inspection, hidden damage may remain |

| Longevity | Excellent with direct deck attachment | Excellent with proper preparation and ventilation |

A shed with shingles in decent shape is a perfect candidate for a metal overlay. However, if you have multiple shingle layers or obvious structural issues, a complete tear-off is the wiser choice.

Pre-Installation Checklist: Is Your Shed Ready?

Before installing metal roof over shingles on shed, a thorough inspection is crucial to avoid problems later. This pre-installation check ensures your shed is a good candidate for an overlay. While most sheds are suitable, proper preparation is key to a successful project.

Step 1: Inspect the Existing Shingle Roof

The condition of your current shingles determines if an overlay is feasible.

- Curling shingles: Severe curling creates an uneven surface that can show through the new metal. Minor curling is manageable, but extensive issues must be addressed.

- Missing or damaged shingles: These must be repaired or replaced to prevent trapping moisture under the new roof.

- Moss or algae growth: Indicates moisture. The roof should be cleaned and dried before installation.

- Multiple shingle layers: Most building codes limit roofing to two layers. If your shed already has two layers, a complete tear-off is required.

Curling and damaged shingles must be addressed before an overlay.

Step 2: Evaluate the Roof Deck and Structure

Investigate the condition of the underlying structure.

- Soft spots: Spongy areas indicate rotted sheathing that must be cut out and replaced with fresh material.

- Signs of rot or water damage: Carefully inspect rafters and sheathing for discoloration or damage. If you’ve had leaks, see our guide on what to do about a leaky roof.

- Structural capacity: Ensure the shed’s frame can handle the added weight of the new roof system, including furring strips and panels.

- Shed ventilation: Proper airflow is crucial to prevent condensation between the old and new roof layers.

Step 3: Gather Your Materials

Understanding the components ensures a quality installation.

- Metal panels: Exposed fastener panels like corrugated or R-panels are durable and cost-effective for sheds.

- Synthetic underlayment: A vital moisture barrier that also protects the metal from the abrasive shingles.

- Furring strips: 1×4 or 2×2 lumber that creates a critical air gap and a flat fastening surface.

- Specialized fasteners: Roofing screws with neoprene washers create a watertight seal.

- Sealant tape and flashing: Essential for sealing overlaps, edges, and penetrations to keep water out.

- Drip edge installation: Provides a finished look and directs water away from fascia. Learn more at our guide on drip edge installation metal roof.

Professional installation ensures the correct, high-quality materials are used. For a complete overview, see our guide to roofing materials.

Step-by-Step Guide: Installing Metal Roof Over Shingles on Shed

With the prep work done, it’s time for the change. Installing metal roof over shingles on shed is a straightforward process when done correctly. Proper surface preparation is the key to a professional look and long-term performance.

Preparing for Installing Metal Roof Over Shingles on Shed

- Clean the roof: Sweep off all leaves, pine needles, and other debris.

- Remove loose items: Clear away any old, protruding nails or loose flashing.

- Fix damaged shingles: Secure loose shingles with roofing cement or replace any that are broken.

- Trim tree branches: Cut back any overhanging limbs that could scratch the new metal panels.

Step 4: Install Underlayment and Furring Strips

This step creates the foundation for an effective and long-lasting metal roof overlay.

First, roll out synthetic underlayment over the existing shingles. This modern material acts as a secondary moisture barrier and protects the new metal panels from the abrasive surface of the old shingles, preventing scratches and potential rust.

Next, install furring strips (1×4 or 2×4 lumber) horizontally across the roof, typically spaced 24 inches on center. Screw them through the shingles securely into the roof deck. These strips are critical because they:

- Create an air gap for ventilation, preventing condensation.

- Provide a flat fastening surface, ensuring a smooth, professional look.

- Prevent thermal expansion abrasion by lifting the metal off the shingles.

For more on this, see Why furring strips are essential.

Furring strips provide essential spacing and a solid fastening surface.

Step 5: Attaching the Metal Panels and Trim

This is when the new roof takes shape.

- Install eave trim/drip edge: This is installed first along the lower edges to direct water away from the fascia.

- Place the first panel: This panel must be perfectly square to ensure the rest of the roof is aligned correctly.

- Overlap subsequent panels: Overlap panels according to manufacturer specifications to shed water effectively.

- Secure the panels: Use specialized roofing screws with rubber washers. Drive them through the high ribs of the panel, never the flat pans where water flows, and secure them into the furring strips. Our guide on Properly Attaching Metal Roofing has more details.

Careful layout and measuring ensure a perfectly aligned metal roof.

Finally, install the ridge cap and flashing. The ridge cap covers the peak, while flashing and sealant make all penetrations and edges completely weatherproof. These finishing details are crucial for a long-lasting, leak-free roof.

Long-Term Care and Durability

After your installing metal roof over shingles on shed project is complete, your shed has a durable, low-maintenance roof. A little attention will ensure it performs at its best for decades.

Long-Term Durability After Installing Metal Roof Over Shingles on Shed

- Expected Lifespan: A properly installed metal roof over shingles can easily last 50 years or more. The old shingles underneath even provide an extra layer of insulation and sound dampening.

- Preventing Rust: Modern panels with coatings like Galvalume are highly rust-resistant. The best way to prevent issues is to keep the roof clear of debris like wet leaves, which can trap moisture and wear down the coating over time.

- Checking Fasteners: Periodically check that the roofing screws are tight, especially after severe weather. It’s easy to tighten or replace any that appear loose.

- Cleaning the Metal Roof: Rain typically keeps the roof clean. If you notice dirt or moss buildup, a gentle rinse with a garden hose and a soft brush is all that’s needed. Avoid pressure washers or harsh chemicals, as they can damage the finish.

The air gap created by the furring strips will continue to provide ventilation, preventing moisture buildup and ensuring your roof performs well for its entire lifespan.

For more specific guidance on maintaining the edges and trim of your new metal roof, check out More about Metal Roof Eave Trim Installation.

Frequently Asked Questions about Shed Roof Overlays

Here are answers to common questions about installing metal roof over shingles on shed projects.

What type of metal roofing is best for a shed?

For most sheds, exposed fastener panels like corrugated or R-panels are the best choice. They offer an excellent balance of cost-effectiveness, durability, and installation simplicity. While standing seam panels are a premium option with concealed fasteners, they are typically overkill and not cost-effective for a standard storage building.

Do I need a permit to install a metal roof on my shed?

This depends on your municipality and the shed’s size. Many towns don’t require permits for re-roofing small accessory structures (often those under 100 to 150 square feet), as it’s considered maintenance. However, rules vary widely. It’s always wise to check with your local building department before starting any work to avoid potential issues.

How does a shed roof differ from a house roof installation?

Installing metal roof over shingles on shed is generally simpler than a house roof installation for a few reasons:

- Scale: Sheds are smaller and have simpler rooflines with fewer penetrations (like chimneys or vents), which makes the installation faster.

- Code Requirements: While safety and quality are still paramount, codes for accessory structures are often more flexible than for primary homes.

- Heating: Most sheds are unheated, which reduces concerns about ice dams and complex condensation issues that can affect a heated home.

- Cost: Metal roof installations can range from $120 to $900 per square foot depending on materials and complexity. Sheds typically fall on the lower end of this range due to their simplicity. Please note that these are average costs based on internet data and not actual costs for Chris Battaini Roofing and Seamless Gutters. Our pricing is customized to each project’s specific needs.

Conclusion

Installing metal roof over shingles on shed is a smart investment for durable, long-lasting protection. By building upon your existing shingles with the proper underlayment, furring strips, and quality metal panels, you create a robust system that can last over 50 years—potentially the last roof your shed will ever need.

The key takeaways are simple: a thorough inspection, proper preparation, and attention to installation details are what ensure decades of worry-free performance. The use of furring strips and synthetic underlayment is critical to the success of the project.

Professional installation benefits are significant. When you work with Chris Battaini Roofing and Seamless Gutters, you get owner-led, on-site service, ensuring every detail is handled correctly. Our expertise with overlay installations and exceptional workmanship warranties provide peace of mind that your investment is protected.

Your shed won’t just look better; it will better protect your belongings and add value to your property for decades to come.

For a durable, long-lasting solution for your shed or home, explore your Metal Roofing options with our expert team.

Chris Battaini Roofing and Seamless Gutters proudly services Berkshire, Hampden, Hampshire, and Franklin Counties in Massachusetts.