The Truth About Modern Flat Roofing

High quality flat roofing systems have evolved dramatically in recent years, offering property owners exceptional durability, energy efficiency, and design flexibility. If you’re researching flat roof options, here’s what defines high quality:

Top 5 High Quality Flat Roofing Materials Compared:

| Material | Lifespan | Cost Range | Best For |

|---|---|---|---|

| EPDM Rubber | 25-50 years | $4-$13 per sq ft | Durability, simplicity, budget-conscious projects |

| TPO | 20-30 years | $4-$14 per sq ft | Energy efficiency, reflectivity, moderate budgets |

| PVC | 20-30+ years | $4-$12 per sq ft | Chemical resistance, restaurants, longevity |

| Modified Bitumen | 15-20 years | $4-$8 per sq ft | High foot traffic, multi-layer protection |

| Standing Seam Metal | 40-70 years | $10-$35 per sq ft | Maximum lifespan, extreme weather resistance |

Flat roofs aren’t actually flat – they have a slight pitch (typically 1/4 inch per foot) to ensure proper drainage. This subtle slope is just one example of how modern flat roofing systems blend practical engineering with clean aesthetics.

When choosing a flat roof for your home or commercial building, the material selection directly impacts your long-term satisfaction. The right choice depends on your specific needs:

- Climate considerations – Some materials perform better in Massachusetts winters than others

- Budget constraints – Initial costs range widely, but cheaper isn’t always better

- Energy efficiency goals – White reflective membranes can reduce cooling costs by up to 15%

- Expected foot traffic – Different systems handle maintenance traffic differently

- Desired lifespan – The longest-lasting options typically cost more upfront

“Modern flat roofs can last 50+ years with proper installation and maintenance,” notes industry research. “But material selection is just the first step – quality installation and regular maintenance are equally crucial for longevity.”

Whether you’re replacing an existing flat roof or planning new construction, understanding the differences between high-quality options will help you make an informed decision that balances upfront investment against long-term performance.

Relevant articles related to high quality flat roofing:

– flat roofing materials

– types of flat roofs

What Makes a High Quality Flat Roofing System?

When it comes to flat roofing, quality isn’t just a nice-to-have—it’s essential for protecting your investment. At Chris Battaini Roofing, we evaluate flat roofing systems against several critical performance benchmarks that separate the exceptional from the merely adequate.

A truly high quality flat roofing system starts with waterproofing integrity. After all, keeping water out is your roof’s primary job! Premium systems feature multiple waterproofing layers and carefully sealed seams that prevent even the smallest leaks.

Here in New England, we know all too well how nor’easters can test a roof’s limits. That’s why wind uplift resistance is non-negotiable for quality flat roofs. Your roof needs proper attachment methods and edge securement to stay put when those winter winds howl.

Daily life happens on and around your roof. From maintenance foot traffic to fallen branches, puncture resistance protects your investment from the unexpected. Premium membranes offer superior thickness and durability compared to budget alternatives.

The comfort inside your building—and your energy bills—depend heavily on your roof’s insulation R-value. Higher values mean better thermal performance, creating a more comfortable interior while reducing heating and cooling costs year-round.

Water should never stand on your roof. Proper drainage slope (minimum ¼-inch per foot) ensures water flows to drains rather than creating damaging ponds that can compromise your roof’s integrity over time.

Beyond performance, quality systems meet or exceed all local building codes for fire resistance, structural loads, and energy efficiency. They’re also designed with sustainability in mind—considering environmental impact, recyclability, and energy-saving potential throughout their lifecycle.

More info about roof inspection services

Core Components of a Premium Assembly

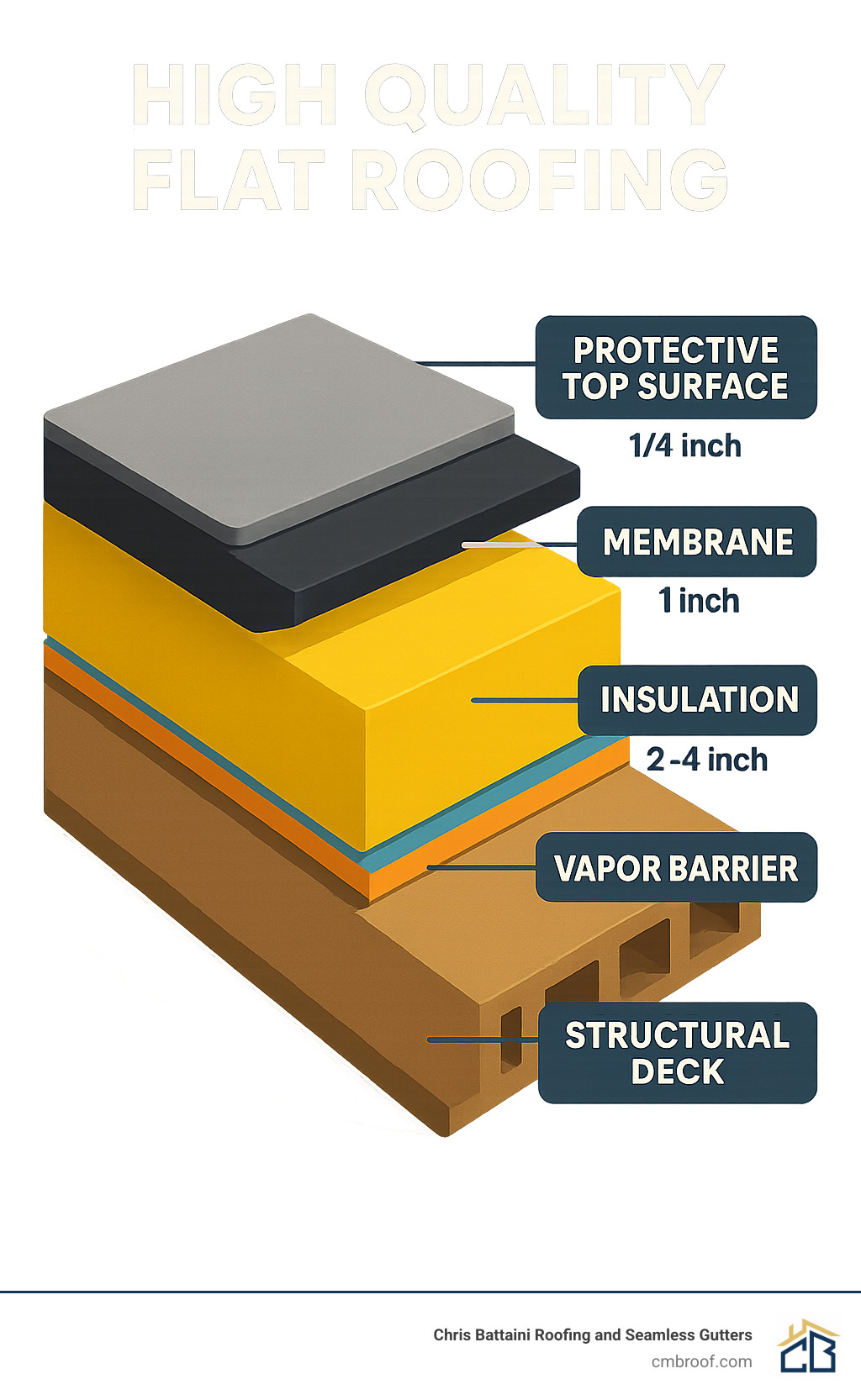

Think of your flat roof as a carefully engineered system where each layer plays a vital role in protecting your property:

The journey begins with the structural deck—your roof’s foundation. Whether made of concrete, metal, or wood, this component must support everything above it plus seasonal snow loads and any rooftop equipment.

Moisture trying to escape from your building’s interior can wreak havoc on your roof system. That’s why a vapor barrier is essential, preventing condensation that could deteriorate your insulation and roofing materials prematurely.

The insulation layer—typically rigid polyisocyanurate (“polyiso”) boards—provides crucial thermal resistance. Premium systems often feature multiple layers with staggered joints, eliminating thermal bridges that waste energy.

A quality cover board adds impact resistance while creating the smooth surface needed for proper membrane installation. This thin but mighty layer also improves fire protection and dimensional stability.

The membrane itself is what most people think of as the “roof.” This waterproofing layer is your primary weather barrier, available in various materials we’ll explore later in this article.

Depending on your specific system, the surfacing might be a reflective coating, ballast (like gravel or pavers), or a factory-applied finish that protects the membrane from UV damage.

Custom-fabricated flashing pieces seal all roof penetrations, edges, and transitions between different roof sections—often the most vulnerable points in any roofing system.

For buildings with completely flat structural decks, tapered insulation creates the proper slope needed for effective drainage, preventing water accumulation that can lead to leaks and structural damage.

High Quality Flat Roofing vs. Budget Builds (why the difference matters)

The gap between premium and budget flat roofing extends far beyond the initial price tag. When you choose high quality flat roofing, you’re making a decision that will pay dividends for decades.

Premium materials resist UV degradation, thermal cycling, and weathering far better than budget alternatives. While they might look similar on day one, the difference becomes apparent over time. For example, a premium 60-mil EPDM membrane offers substantially better puncture resistance than a budget 45-mil option, providing peace of mind during severe weather events.

Installation expertise matters just as much as material selection. At Chris Battaini Roofing and Seamless Gutters, we’ve seen how proper installation techniques ensure watertight seams, correctly detailed flashing, and secure attachment. Even the best materials will fail prematurely if installed incorrectly.

Looking at the complete financial picture, premium flat roofing typically offers superior return on investment. While a quality system might cost 20-30% more initially, it often lasts twice as long with fewer maintenance issues. This dramatically reduces your total cost of ownership over the roof’s lifetime.

The warranty tells you volumes about a roof’s expected performance. Budget systems might offer 10-15 years of limited coverage, while premium options typically come with 20-30 year warranties covering both materials and workmanship—a reflection of the manufacturer’s confidence in the system’s durability.

When extreme weather strikes—whether it’s heavy snow loads stressing seams or wind-driven rain searching for vulnerabilities—quality systems maintain their integrity while budget builds often fail at the worst possible time.

We proudly serve Berkshire, Hampden, Hampshire, and Franklin Counties in Massachusetts.

High Quality Flat Roofing Materials Round-Up & Comparison

Let’s take a friendly tour through today’s top flat roofing materials, comparing what each brings to the table for your building. Whether you’re replacing an existing roof or planning new construction, understanding these options will help you make the right choice for your specific needs.

| Material | Lifespan | Cost/sq ft* | Energy Rating | Maintenance | Foot Traffic | Best Applications |

|---|---|---|---|---|---|---|

| EPDM | 25-50 yrs | $4-$13 | Low (black), High (white) | Low | Moderate | Large commercial, budget-conscious projects |

| TPO | 20-30 yrs | $4-$14 | High | Moderate | Moderate | Energy-efficient buildings, retail, offices |

| PVC | 20-30+ yrs | $4-$12 | High | Low | High | Restaurants, chemical exposure areas |

| Modified Bitumen | 15-20 yrs | $4-$8 | Moderate | Moderate | High | High-traffic roofs, phased installation |

| BUR | 20-30 yrs | $4-$7 | Low-Moderate | Moderate | Very High | Industrial buildings, equipment-heavy roofs |

| Standing-Seam Metal | 40-70 yrs | $10-$35 | High (with coating) | Very Low | Low | Long-term investments, aesthetic focus |

*Average internet costs range widely and may run three times higher on complex builds. These are not actual costs for Chris Battaini Roofing and Seamless Gutters.

Did you know TPO roofing has been gaining tremendous popularity in recent years? Check out this video on TPO roofing’s growing popularity to see why so many building owners are making the switch. For a deeper dive into all your material options, visit our detailed guide to Flat Roofing Materials.

EPDM Rubber – The 50-Year Workhorse

When it comes to reliable performance year after year, EPDM has earned its reputation as the dependable workhorse of high quality flat roofing materials. This synthetic rubber membrane has been quietly protecting buildings since the 1960s, and it continues to impress with its remarkable durability.

What makes EPDM so special? For starters, its exceptional flexibility means it remains pliable even during our harsh Massachusetts winters. This rubber can stretch up to 300% before breaking, allowing it to handle building movement and temperature changes without cracking. When properly installed and maintained, EPDM can last up to 50 years – making it one of the longest-lasting membrane options available.

Installation options are versatile too. EPDM can be fully adhered (glued down), mechanically attached with fasteners, or ballasted with stone, giving us flexibility to match your building’s specific needs. It naturally resists damage from UV rays and ozone without needing additional treatments, and when damage does occur, repairs are straightforward using compatible adhesives and patches.

There are a few things to consider with EPDM. Traditional black sheets absorb heat, which can be helpful during cold New England winters but might increase summer cooling costs. White EPDM reflects heat better but typically costs more and shows dirt more readily. The traditional seam adhesives can be a potential weak point, though newer seaming technologies have greatly improved reliability.

For large commercial applications where budget matters but performance can’t be compromised, EPDM offers the perfect balance. Its proven track record in our challenging Northeast climate makes it a smart choice for many of our clients.

TPO – Reflective & Budget-Smart

TPO (Thermoplastic Polyolefin) has quickly become a favorite high quality flat roofing option, especially for building owners looking to balance energy efficiency with reasonable upfront costs.

The standout feature of TPO is its superior UV reflectivity. White TPO membranes can reflect up to 85% of the sun’s rays, potentially reducing your summer cooling costs by up to 15%. This makes TPO an excellent choice if your building has high cooling demands or you’re looking to improve your energy efficiency.

Unlike adhesive-based systems, TPO seams are heat-welded to create a molecular bond that’s actually stronger than the membrane itself. This virtually eliminates seam failures – one of the most common causes of roof leaks. At a typical price point between $4-$14 per square foot (based on internet data, not actual costs for Chris Battaini Roofing and Seamless Gutters), TPO offers excellent value, especially when you factor in the potential energy savings.

While white is most common for its reflective properties, TPO also comes in gray and tan to complement your building’s appearance. It naturally resists algae, bacteria, plant roots, and many common chemicals, keeping your roof looking clean and performing well for years.

There are a few considerations with TPO. Some membranes may experience slight shrinkage in very high temperatures, though newer formulations have improved stability. Quality can vary between manufacturers, which is why working with experienced contractors familiar with specific products is so important. And while TPO has been in use for over 20 years, it doesn’t have quite the decades-long track record of some alternatives.

TPO has become particularly popular for retail buildings, warehouses, and office complexes throughout Massachusetts. The balance of upfront affordability and long-term energy savings makes perfect sense for budget-conscious property owners who still want high performance.

PVC – Chemical & Fire Resistant Champ

When chemical resistance and durability are top priorities, PVC (Polyvinyl Chloride) stands out as the champion among high quality flat roofing materials. This premium option excels in specialized applications where other membranes might struggle.

PVC’s superior chemical resistance makes it virtually impervious to oils, greases, and harsh chemicals – perfect for restaurants, industrial facilities, and laboratories. Like TPO, PVC seams are heat-welded rather than glued, creating molecular bonds that eliminate the most common failure point in roofing systems.

Fire safety is another area where PVC shines. The material is inherently fire-resistant and can actually self-extinguish, enhancing building safety and potentially reducing insurance costs. With a track record dating back to the 1960s, PVC has demonstrated reliable performance for 30+ years when properly installed.

High-quality PVC membranes also have excellent “memory,” allowing them to self-heal small punctures. This unique property adds another layer of protection against leaks and extends the roof’s service life.

PVC does come with some considerations. While still competitive with other single-ply membranes, it typically commands a slight premium over TPO and EPDM. Proper installation requires specialized welding equipment and experienced technicians. Older or lower-quality PVC formulations can suffer from plasticizer migration (causing brittleness), though modern, high-quality PVC addresses this issue.

PVC is particularly well-suited for rooftop restaurants where grease exposure from kitchen exhaust would quickly degrade other membranes, laboratory buildings where chemical resistance is paramount, and food processing facilities where sanitation and chemical cleaning are routine.

For property owners throughout Western Massachusetts looking for a premium solution with specialized chemical resistance, PVC offers exceptional performance and peace of mind.

Modified Bitumen – Tough for Foot Traffic

Modified Bitumen (often called “mod bit”) brilliantly combines traditional asphalt technology with modern polymer science to create a high quality flat roofing system that handles heavy foot traffic with ease.

The multi-layer protection of mod bit systems – typically installed in two or more layers – provides redundant waterproofing and excellent puncture resistance. This multi-ply design distributes weight and impact, making it ideal for roofs that see regular maintenance traffic or house mechanical equipment requiring frequent servicing.

Installation flexibility is another advantage. Modified bitumen comes in self-adhesive, torch-applied, or hot-mopped varieties to suit different building conditions and contractor capabilities. The top layer often features a granulated cap sheet with embedded granules that provide UV protection, fire resistance, and an attractive finished appearance.

When damage does occur, repairs are straightforward and can be completed with minimal disruption – an important consideration for busy commercial properties.

Modified bitumen incorporates polymer modifiers (SBS-styrene butadiene styrene or APP-atactic polypropylene) that significantly improve the natural properties of asphalt. These modifiers improve flexibility, especially in cold weather, and increase the roof’s resistance to the thermal cycling we experience in New England.

There are some trade-offs to consider. Modified bitumen typically lasts 15-20 years – less than some single-ply options, though premium installations can extend this lifespan. It’s heavier than single-ply systems, which may be a consideration for structures with limited load capacity. And torch-applied systems require strict safety protocols during installation to prevent fire hazards.

For commercial buildings in Massachusetts with rooftop equipment requiring regular maintenance, modified bitumen offers an excellent balance of durability and cost-effectiveness. Its multi-layer design provides peace of mind for building owners concerned about puncture resistance.

BUR (Built-Up Roofing) – Century-Old Classic

Built-Up Roofing (BUR) is the time-tested veteran of high quality flat roofing systems, with a remarkable track record spanning over a century. Often called a “tar and gravel” roof, modern BUR systems have evolved while maintaining their fundamental strengths.

The exceptional durability of BUR comes from its multiple layers – typically 3-5 plies – which provide redundant protection against leaks and punctures. The top layer of stone ballast protects the underlying membrane from UV degradation and physical damage while providing excellent fire resistance.

With over 100 years of real-world application, BUR has demonstrated reliable performance in every climate condition imaginable. The robust, multi-layer design with gravel surfacing makes BUR the gold standard for roofs with heavy foot traffic or equipment maintenance needs.

One of BUR’s unique advantages is its self-healing properties – the bituminous layers can flow slightly at high temperatures, helping to seal small cracks or punctures without intervention.

There are some considerations with BUR systems. Hot asphalt application produces strong odors during installation, which may be disruptive for occupied buildings. It’s among the heaviest roofing systems, requiring adequate structural support. Installation is weather-sensitive and cannot be done in cold or wet conditions, limiting application seasons in Massachusetts. And it’s more labor-intensive, requiring larger crews and more time to install compared to single-ply systems.

Modern BUR systems have evolved to incorporate fiberglass mat reinforcement instead of traditional organic felts, improving dimensional stability and longevity. Some systems also use cold-applied adhesives to reduce odor concerns.

For industrial buildings, warehouses, and structures where durability trumps all other considerations, BUR remains a reliable choice. Its multi-layer redundancy provides peace of mind for building owners who prioritize long-term performance over initial cost.

Standing-Seam Metal – Ultimate Lifespan

Standing-seam metal represents the premium tier of high quality flat roofing systems, offering best longevity and distinctive aesthetics. While technically suitable for low-slope applications (minimum 1/4:12 pitch), it’s most commonly used on roofs with at least a 1:12 pitch.

The exceptional lifespan of standing-seam metal is its most compelling feature – with proper installation, these roofs can last 40-70 years, making them the longest-lasting flat roofing option available. The defining feature of standing-seam systems is that all fasteners are hidden beneath the raised seams, eliminating potential leak points that plague other roofing types.

For buildings in areas prone to severe weather, the interlocking panel design provides superior hurricane resistance and excellent wind uplift protection – critical during the nor’easters we sometimes experience in New England.

Maintenance requirements are minimal compared to other flat roofing systems, with simple periodic inspections often sufficient to ensure continued performance. Modern metal roofs can be finished with reflective coatings that rival white membrane systems for energy efficiency, combining longevity with environmental benefits.

The premium performance does come with considerations. Standing-seam metal is typically the most expensive flat roofing option, with costs ranging from $10-$35 per square foot (based on internet data, not actual costs for Chris Battaini Roofing and Seamless Gutters). Installation requires experienced professionals with specific metal roofing expertise. Without proper insulation and installation techniques, metal roofing can transmit more noise during rain or hail. And metal expands and contracts significantly with temperature changes, requiring proper design to accommodate this movement.

Standing-seam metal roofing is ideal for buildings where long-term value outweighs initial cost concerns. The system’s ability to last for many decades with minimal maintenance makes it particularly attractive for institutional buildings, high-end commercial properties, and residential applications where aesthetics are a priority.

Factors That Drive Lifespan, Energy Efficiency & Total Cost of Ownership

When you’re investing in a high quality flat roofing system, looking at just the initial price tag tells only part of the story. The true value emerges when you consider how long your roof will last and how it affects your building’s energy consumption over decades.

Think of your flat roof as a long-term relationship rather than a quick fix. Several key factors will determine whether that relationship thrives or becomes troublesome:

Your local climate plays a starring role in how your roof performs. Here in Massachusetts, roofing materials must stand up to dramatic seasonal changes – from scorching summer days to bone-chilling winter nights. These freeze-thaw cycles put enormous stress on seams and flashings, while heavy snow loads test the structural integrity of the entire system. A roof that might last 30 years in a mild climate might struggle to reach 20 years in our New England weather.

Insulation thickness does double duty by lowering your energy bills and protecting your roof membrane. Higher R-values mean less heat transfer, which translates to lower heating and cooling costs. But there’s a hidden benefit too – proper insulation moderates temperature fluctuations in the membrane itself, reducing the thermal stress that leads to premature aging and cracks.

The color of your roof might seem like just an aesthetic choice, but it significantly impacts energy efficiency. White or light-colored membranes can reflect up to 85% of the sun’s rays, potentially slashing your summer cooling costs by 15% or more compared to dark surfaces. For buildings with high cooling demands, this reflectivity can translate to thousands in savings annually.

Membrane thickness is another factor where quality truly matters. Premium membranes with greater thickness (60-90 mils versus standard 45 mils) provide substantially better resistance to punctures and weathering. This additional material often adds just a small percentage to your upfront cost while significantly extending service life.

A proactive maintenance schedule might be the single most powerful way to maximize your roof’s lifespan. Regular inspections and preventive care can literally double how long your roof lasts. Think about that – the same roof might give you 15 years with neglect or 30 years with proper care. The math makes the case for maintenance pretty compelling.

Don’t overlook potential tax credits and incentives when calculating total cost. Energy-efficient roofing systems may qualify for federal, state, or utility rebates that can offset a significant portion of your initial investment.

The smartest choice varies dramatically depending on your specific building. A warehouse in Pittsfield with heavy HVAC equipment might benefit most from a robust BUR system that can handle maintenance traffic, while an office building in Springfield might see better returns from a reflective TPO membrane that reduces cooling costs.

Climate & Location – Choosing the Right Membrane

New England weather demands roofing systems that can handle a bit of everything. When we sit down with clients to discuss material options, we consider several location-specific challenges that will test your roof daily:

Snow Load Considerations

Massachusetts buildings must withstand significant snow accumulation, sometimes for weeks at a time. This affects your flat roof in ways that building owners in warmer climates never have to consider. Membrane flexibility becomes crucial when temperatures plummet below zero, as some materials become brittle and prone to cracking. Both EPDM and PVC maintain excellent flexibility even in bitter cold, making them particularly well-suited for our region. By contrast, some TPO formulations can become more rigid in extreme cold, potentially compromising performance.

Ponding Risk Assessment

Flat roofs in our region face increased ponding risk due to our unique weather patterns. Heavy snow loads can cause temporary deck deflection, creating low spots where water collects. Freeze-thaw cycles can block drainage paths with ice, and spring rain combined with snowmelt creates high water volumes that test your roof’s drainage capacity. Modified bitumen and BUR systems typically handle occasional ponding better than single-ply membranes, though properly designed single-ply systems with adequate slope perform well too.

UV Intensity Management

While Massachusetts doesn’t experience the extreme UV exposure of Florida or Arizona, our summer sun can still accelerate membrane aging. White reflective membranes like TPO and PVC offer distinct advantages by reducing membrane temperature (potentially extending lifespan), lowering cooling costs during summer months, and helping mitigate the urban heat island effect in more densely developed areas.

Coastal Wind Considerations

For properties in coastal areas, wind uplift resistance becomes a critical factor. Standing-seam metal and fully-adhered membrane systems typically offer superior wind performance compared to mechanically-fastened or loose-laid systems. This becomes particularly important during nor’easters that can test even the most robust installations.

The contrast between Massachusetts and Florida requirements illustrates these regional differences. In Florida, hurricane resistance and heat reflection are primary concerns, while in Massachusetts, freeze-thaw cycling and snow load accommodation take precedence.

Maintenance & Inspection – Small Effort, Big Savings

The most cost-effective way to maximize your high quality flat roofing investment isn’t buying the most expensive system – it’s taking care of whatever system you choose. A small, consistent investment in preventive care yields tremendous returns in extended service life.

We recommend comprehensive roof inspections at least twice yearly – once in spring to identify any winter damage, and again in fall to prepare for the upcoming winter season. These inspections should thoroughly examine the entire membrane surface, all seams and transitions, flashings around penetrations and edges, drainage systems, and any signs of ponding water. Think of it like a dental checkup – catching small issues before they become big problems.

Clogged drains are among the most common causes of flat roof failures, yet they’re entirely preventable. Regular maintenance should include removing leaves and debris from drain covers and scuppers, checking internal drain lines for blockages, and ensuring positive flow through the entire drainage system. After a good rainfall, documenting drainage patterns can help identify developing issues before they cause leaks.

Even with high quality flat roofing materials, seams require periodic attention. EPDM seams typically need inspection every 5-7 years, while modified bitumen lap seams should be checked annually. TPO and PVC heat-welded seams are more durable but still warrant regular inspection. Catching a failing seam early often means a simple repair rather than extensive water damage.

Protective coatings can extend roof life by refreshing UV protection and waterproofing. Aluminum coatings for modified bitumen typically need refreshing every 5-7 years, acrylic coatings for EPDM every 7-10 years, and silicone coatings for various substrates every 10-15 years. These coatings are like sunscreen for your roof – they protect the underlying material from the elements.

By implementing a structured maintenance program, building owners can often double the effective lifespan of their roofing investment. A properly maintained TPO roof might last 30+ years instead of the typical 20 years. When you spread the original cost over twice the lifespan, the financial benefits become substantial.

More info about commercial roof repair

Warranty Basics Every Owner Should Demand

A comprehensive warranty is essential protection for your high quality flat roofing investment, but not all warranties offer equal protection. Understanding the fine print can save you thousands down the road.

Material vs. Workmanship Coverage

Most roofing failures actually stem from installation errors rather than material defects. That’s why savvy building owners look for warranties that cover both aspects. Material warranties (from the manufacturer) protect against premature membrane deterioration, while workmanship warranties (from the contractor) cover installation-related issues. At Chris Battaini Roofing and Seamless Gutters, we stand behind our work with exceptional workmanship warranties that complement manufacturer material coverage.

Warranty Term Options

Standard warranty lengths vary by material and quality tier. While 10-year warranties are typical for basic installations, 20-year warranties represent the industry standard for quality systems. For premium installations with upgraded components, 30-year warranties provide extended peace of mind. Longer warranties usually require higher-grade materials and more rigorous installation standards – which is actually good news for your roof’s performance.

No-Dollar-Limit (NDL) Protection

The gold standard in roofing warranties is NDL coverage, meaning the manufacturer will cover the full cost of repairs regardless of the original roof price. This contrasts sharply with prorated warranties that depreciate coverage over time, potentially leaving you with minimal protection when you need it most. The difference becomes particularly significant on larger buildings where repair costs can be substantial.

Transferability Provisions

For commercial properties that might change hands, transferable warranties add significant value. Look for simple transfer procedures with minimal fees, no reduction in coverage upon transfer, and clear documentation requirements. A transferable warranty can actually increase your property value when it’s time to sell.

Exclusions and Limitations

Be wary of warranties with extensive exclusions. Some red flags include ponding water limitations (especially problematic in New England), restrictive wind speed caps below realistic local conditions, and requirements for paid manufacturer inspections that add ongoing costs.

The most valuable warranties come from established manufacturers with decades in business and the financial stability to honor long-term commitments. When evaluating roofing proposals, the warranty should be a central consideration, not an afterthought. A comprehensive warranty from a reputable company isn’t just paperwork – it’s protection for one of your building’s most critical components.

We proudly serve Berkshire, Hampden, Hampshire, and Franklin Counties in Massachusetts.

Installation & Upkeep Best Practices for High Quality Flat Roofing

The true value of a high quality flat roofing system emerges through proper installation and consistent maintenance. At Chris Battaini Roofing and Seamless Gutters, we’ve seen how installation quality directly impacts performance—even premium materials will disappoint if installed incorrectly.

Creating proper slope is foundational to flat roof success. Industry standards require a minimum pitch of ¼-inch per foot (2%) to ensure water flows where it should. In New England, where snow and ice are seasonal challenges, this isn’t just a recommendation—it’s essential. We achieve this either through structural deck design, carefully installed tapered insulation systems, or strategic cricket placement at key drainage points.

The warm-roof vs. cold-roof decision is particularly important in our Massachusetts climate. Warm-roof designs (where insulation sits above the deck) typically outperform cold-roof alternatives by keeping the structural deck above the dew point. This prevents condensation within the assembly and significantly reduces thermal cycling stress on the membrane—a common cause of premature aging in our freeze-thaw environment.

Professional installation requires more than basic roofing knowledge. Our crews maintain manufacturer certifications for specific systems and receive ongoing training in evolving best practices. For thermoplastic membranes like TPO and PVC, precise temperature control during hot-air welding makes the difference between a watertight seal and future leaks. We calibrate our equipment daily based on ambient conditions and perform test welds before starting each section.

Safety protocols do more than protect our workers—they ensure quality work. Proper fall protection systems that don’t damage the roof surface, fire watch procedures for torch-applied systems, and careful weather monitoring prevent installation during adverse conditions that could compromise long-term performance.

Modern technology has transformed verification methods as well. Electronic leak detection systems like low-voltage vector mapping and infrared scanning can identify potential issues before they become problems, providing peace of mind that your investment is truly watertight from day one.

Red Flags During Install That Shorten Roof Life

Knowing what to watch for during installation can save you from premature roof failure. When we train new team members, we emphasize these critical warning signs that signal substandard workmanship.

Poor fastening patterns create immediate vulnerability to wind damage. Watch for fasteners spaced too far apart, wrong fastener types for your specific deck material, or inconsistent attachment patterns. Overdriven fasteners that damage the membrane are particularly troublesome—they create weak points from day one.

Membrane wrinkles and fishmouths might seem like minor aesthetic issues, but they create stress points that can split over time. Smooth installation isn’t just about looks—it’s about longevity. Fishmouths (openings at seams) provide direct water entry points, while bridging at transitions prevents proper adhesion and creates hidden pathways for moisture.

Trapped moisture during installation is a ticking time bomb. Installing over wet substrates, working during rain without proper protection, or failing to replace wet insulation virtually guarantees future problems. Water trapped within a roof assembly will eventually find its way out—usually by damaging other components along the way.

Flashing shortcuts account for a surprising percentage of roof leaks. Proper flashing at all penetrations and transitions requires meticulous attention to detail—adequate height at walls and curbs (minimum 8 inches), proper corner treatments, secure counter-flashing, and fully sealed termination bars. When contractors rush these critical details, problems inevitably follow.

Insufficient curing time undermines adhesive performance. Premature foot traffic on uncured adhesives, sealing details before solvent evaporation, and rushing temperature-sensitive applications all compromise long-term adhesion. Some adhesives require 24+ hours to develop full strength—patience during installation pays dividends in performance.

Our owner-led service model ensures these issues never compromise your roof. Direct supervision and thorough documentation of proper installation procedures mean every roof we install meets our exacting standards—because we’re on site making sure it happens.

Scheduled Maintenance Checklist

A structured maintenance program is your roof’s best friend. Even the finest high quality flat roofing systems benefit from regular attention that catches small issues before they become major problems.

Drain inspection should top your quarterly maintenance list. Clear all drain covers and strainers, remove debris from scuppers and gutters, and check for signs of ponding water. After rainfall, verify positive drainage—water should completely clear within 48 hours. A single clogged drain can cause significant damage during heavy precipitation.

Debris removal protects your membrane from physical damage and chemical degradation. Clear all loose material from the roof surface, remove vegetation (which can root into membranes), and check for sharp objects that might puncture the surface. Pay special attention after storms, when wind-blown debris often accumulates.

Membrane cleaning preserves both appearance and function. Gently clean visible dirt and contaminants using manufacturer-approved cleaning solutions—harsh chemicals or abrasive tools can do more harm than good. White reflective membranes particularly benefit from regular cleaning to maintain their energy-saving properties.

Twice yearly (spring and fall), conduct more thorough inspections. Check all field seams for separation, inspect membrane-to-flashing transitions, verify sealant integrity at terminations, and look for signs of movement or stress. These connection points are most vulnerable to failure and benefit most from preventive attention.

Flashing examination should include all penetrations, walls, and edges. Verify counter-flashing remains secure and look for signs of metal fatigue or separation. These transitional areas experience the greatest stress during thermal cycling and require special attention.

Address minor puncture patching promptly using manufacturer-approved materials and techniques. Document all repairs with photographs for warranty purposes and verify complete adhesion after completion. Small repairs done correctly prevent bigger problems later.

Annual comprehensive roof surveys provide valuable documentation of condition trends. Photograph the entire roof, measure membrane thickness at multiple points to track wear patterns, and evaluate overall drainage performance. Consider specialized inspections like infrared scanning to detect subsurface moisture before it causes visible damage.

This maintenance investment typically costs just a fraction of premature replacement expenses. Many of our clients find that professional maintenance extends their roof’s useful life by 25-50%—turning a 20-year roof into a 30-year roof with minimal effort.

We proudly serve Berkshire, Hampden, Hampshire, and Franklin Counties in Massachusetts.

High Quality Flat Roofing FAQs

How long will a high quality flat roof last?

When clients ask about longevity, I always tell them that a high quality flat roofing system’s lifespan varies dramatically based on material choice, installation quality, and how well it’s maintained over time.

EPDM rubber roofs typically last 25-50 years when properly installed and maintained. There’s a good reason we often call EPDM the “workhorse” of commercial roofing—its simple design means fewer components that can fail over time. I’ve seen 30-year-old EPDM roofs still performing beautifully with regular care.

TPO membranes generally provide 20-30 years of service, with newer formulations pushing toward the upper end of that range. The key with TPO is regular seam inspection—those heat-welded joints are strong, but they deserve attention during maintenance visits.

PVC roofing systems deliver 20-30+ years of protection, with premium installations sometimes exceeding three decades in ideal conditions. The chemical resistance that makes PVC perfect for restaurants also helps it maintain integrity longer than many alternatives.

Modified bitumen typically lasts 15-20 years for standard installations, though premium multi-ply systems can reach 25 years with proper maintenance. The redundant layers in a quality mod-bit roof provide excellent protection against the elements.

Built-Up Roofing (BUR) systems generally last 20-30 years, with regular recoating extending life considerably. There’s something reassuring about those multiple layers of protection in a traditional BUR system.

Standing-seam metal roofing stands apart with an impressive 40-70 year lifespan, making it the longest-lasting option available. Yes, the initial investment is higher, but when you calculate the decades of virtually maintenance-free service, the value becomes clear.

In our experience at Chris Battaini Roofing and Seamless Gutters, three factors most significantly impact how long your roof will actually last:

- Installation quality – Even the finest materials will fail prematurely if poorly installed

- Maintenance frequency – Regular care can literally double a roof’s effective lifespan

- Climate exposure – Our New England weather puts unique stresses on roofing systems

We’ve consistently seen properly maintained premium systems exceed manufacturer lifespan estimates by 20-30%. That’s the power of quality installation combined with regular professional maintenance.

What’s the most energy-efficient flat roofing material?

Energy efficiency in flat roofing primarily comes down to how well a material reflects sunlight and releases absorbed heat. Several options offer excellent performance, but they each have their own strengths.

TPO (Thermoplastic Polyolefin) typically provides the best overall balance of energy efficiency characteristics. A quality white TPO membrane reflects up to 85% of solar radiation, maintains its reflectivity well over time, and can reduce cooling costs by 15-30% compared to dark roofs. It’s available in white, tan, and gray (though white offers maximum efficiency), and easily complies with ENERGY STAR® and LEED requirements. For buildings with significant cooling demands, TPO often delivers the best return on investment.

PVC (Polyvinyl Chloride) offers similar reflective properties with excellent solar reflectance (typically 80-85%) and superior long-term reflectivity retention. It costs slightly more than TPO but provides improved chemical resistance for specialized applications like restaurant roofs.

White EPDM provides good energy efficiency with reflectivity of 75-80% (compared to just 5-10% for traditional black EPDM). It typically costs more than black EPDM and may require more frequent cleaning to maintain its reflective properties, but offers excellent durability.

Metal roofing with cool coatings represents the premium performance option. With reflectivity ranging from 60-85% depending on the specific coating, exceptional durability of those reflective properties, and the longest overall lifespan, metal offers compelling long-term value despite its higher initial cost.

For buildings here in Massachusetts, the ideal choice often depends on the balance between heating and cooling seasons. In buildings with significant air conditioning loads, white reflective membranes typically provide the best return. For minimally cooled structures, dark membranes that absorb solar heat can sometimes reduce winter heating demands.

The most energy-efficient solution often involves combining a reflective roof with adequate insulation (minimum R-30 in our climate zone) to optimize year-round performance. This holistic approach delivers the best long-term energy savings.

How can I tell if my flat roof needs repair or replacement?

Knowing when to repair versus replace your flat roof can save thousands in preventable damage. After inspecting hundreds of commercial roofs across Western Massachusetts, we’ve identified several reliable indicators that help property owners make this important decision.

Signs repair may be sufficient:

When we see isolated leaks confined to a single area, this often indicates a localized issue that can be repaired without full replacement. Similarly, surface deterioration like crazing or checking that hasn’t penetrated to lower layers can typically be addressed with repairs or protective coatings.

Minor blistering that doesn’t expose the reinforcement can often be monitored rather than immediately repaired. Problems confined to flashings around penetrations, walls, or edges usually allow for targeted repairs rather than complete replacement.

Age is another important factor—roofs that haven’t reached three-quarters of their expected service life are generally good candidates for repair rather than replacement. A 15-year-old TPO roof with isolated issues, for instance, likely has plenty of serviceable life remaining after repairs.

Signs replacement is likely needed:

Multiple or recurring leaks in different areas often signal that the membrane has reached the end of its useful life. When you’re patching one leak only to find another appearing elsewhere, it’s usually time to consider replacement.

Widespread membrane fatigue showing as extensive cracking, splitting, or brittleness indicates systemic failure rather than isolated problems. This type of deterioration typically can’t be effectively repaired.

Significant ponding water that remains 48+ hours after rainfall accelerates deterioration and often points to structural issues that need addressing during replacement. Similarly, when the insulation beneath the membrane becomes saturated, both insulation and membrane typically require replacement.

Membrane shrinkage (pulling away from walls, curbs, or penetrations) indicates the membrane is contracting and failing at a fundamental level. And of course, a roof that has exceeded its design life is living on borrowed time, even if it appears functional.

The most reliable assessment comes from a professional inspection. At Chris Battaini Roofing and Seamless Gutters, our comprehensive roof evaluations include core samples (when appropriate), seam testing, and detailed documentation to help building owners make informed decisions about repair versus replacement.

We proudly serve Berkshire, Hampden, Hampshire, and Franklin Counties in Massachusetts.

Conclusion & Next Steps

Navigating high quality flat roofing can feel overwhelming, but understanding your options is the first step toward making a sound investment in your property. Throughout this guide, we’ve explored the strengths and considerations of today’s premier flat roofing materials.

Each system offers distinct advantages that might make it perfect for your specific situation:

EPDM shines in its simplicity and proven track record, making it an excellent choice when you need reliable performance without breaking the bank. Its exceptional flexibility handles our Massachusetts winters with ease.

TPO delivers outstanding energy efficiency at a moderate price point, potentially saving you thousands in cooling costs over its lifetime while providing dependable protection for most commercial applications.

PVC stands out for specialized environments where chemical resistance matters, like restaurants and laboratories. Its molecular-bonded seams virtually eliminate one of the most common failure points in roofing.

Modified Bitumen excels when foot traffic is frequent, with its multi-layer design distributing weight and impact to prevent punctures and tears during regular maintenance.

BUR (Built-Up Roofing) continues to prove itself after more than a century, with its redundant protection making it ideal for industrial applications where reliability trumps all other concerns.

Standing-Seam Metal offers best longevity and striking aesthetics, with properly installed systems often outlasting their alternatives by decades, despite the higher initial investment.

Your ideal choice depends on several factors unique to your situation: budget constraints, performance priorities, aesthetic preferences, and the specific demands of your property and climate zone.

At Chris Battaini Roofing and Seamless Gutters, we understand that a roof isn’t just a commodity—it’s a critical investment in your property’s protection and value. That’s why our owner-led service model ensures you work directly with experienced professionals who take personal pride in every installation.

Our exceptional workmanship warranties reflect our confidence in the quality of our installations and our commitment to your long-term satisfaction. We don’t just install roofs; we build relationships with our customers based on trust and proven performance.

Whether you’re planning new construction, facing a complete replacement, or evaluating repair options for your existing roof, we’re here to guide you through the process with honest advice and skilled craftsmanship.

We proudly serve Berkshire, Hampden, Hampshire, and Franklin Counties in Massachusetts, bringing premium roofing solutions specifically custom to our region’s unique climate challenges. Our deep understanding of local conditions ensures your roof will stand up to whatever New England weather throws its way.