Why Stone Coated Steel is a Game-Changer

Stone coated steel roofing installation combines the durability of metal with the classic beauty of traditional roofing materials. This innovative system offers homeowners the best of both worlds – a roof that can last 50+ years while maintaining the aesthetic appeal of shingles, shakes, or tiles.

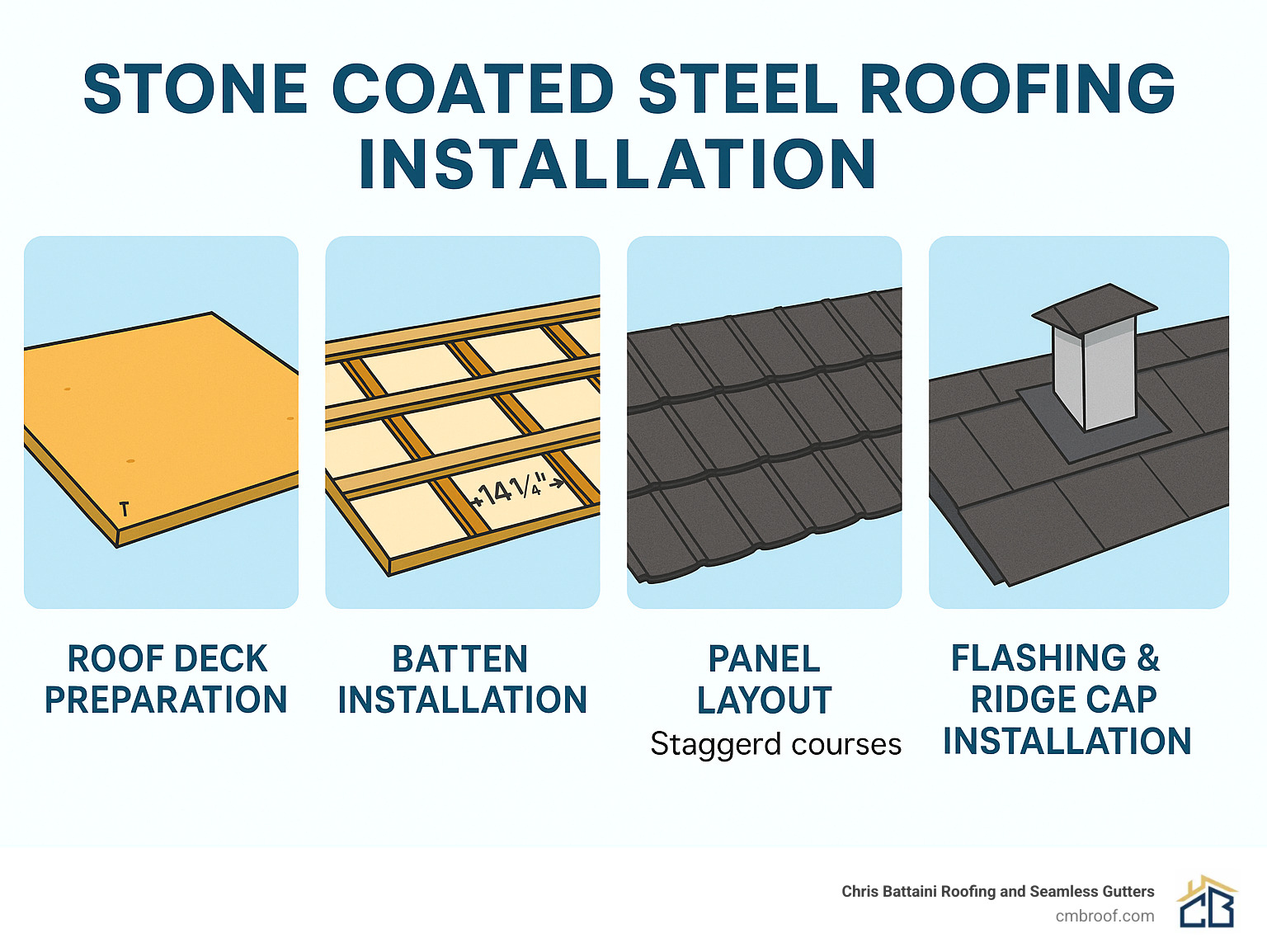

Quick Installation Overview

Installation Methods:

- Direct-to-Deck: Panels installed directly on roof sheathing

- Batten System: Panels mounted on wooden battens for ventilation

Essential Steps:

- Roof deck preparation and underlayment installation

- Batten installation (if using batten method) at 14¼” spacing

- Panel layout from bottom-up, left-to-right in staggered courses

- Flashing installation around penetrations and roof features

- Ridge cap and trim installation for weatherproof finish

The demand for residential metal roofing has seen explosive growth, with market share increasing by 50% between 2019-2022. This surge reflects homeowners’ growing frustration with frequent roof replacements and their desire for long-term value.

Stone coated steel roofing delivers impressive performance metrics:

- Longevity: 50+ years vs. 20-30 years for asphalt shingles

- Energy efficiency: Up to 20% reduction in cooling costs

- Weather resistance: Withstands 120 mph winds and tennis ball-sized hail

- Weight: Under 2 lbs per square foot vs. 8-12 lbs for traditional tiles

The installation process requires specialized tools and techniques, but the results speak for themselves. A properly installed stone coated steel roof may be the last roof your home ever needs.

Stone coated steel roofing installation glossary:

Gearing Up: Essential Prep Work and Safety

Preparation is where great roofs begin. Before the first panel ever leaves the ground, we make sure your roof deck is solid, your underlayment is watertight, and every safety measure is in place.

Roof Deck Inspection and Preparation

- Strip to the deck whenever possible. A tear-off lets us spot hidden rot or sagging sheathing that could shorten the life of your new roof.

- Replace any compromised panels, renail loose sheathing, and confirm the deck is level.

Choosing and Installing Underlayment

- We favor synthetic underlayment for its strength and superior walk-ability.

- Along eaves and valleys, a self-adhered ice & water shield stops ice dams cold.

- All layers are installed shingle-style, bottom to top, with required overlaps and drip edge installation metal roof at the perimeter.

Specialized Tools and Safety First

Required gear includes panel cutters, metal snips, power drills, chalk lines, and only corrosion-resistant fasteners. Every crew member uses:

- Harness and lifeline

- Soft-soled shoes (to prevent panel scuffing)

- Gloves & eye protection

A safe perimeter on the ground and clearance from power lines finish the setup. Proper prep may add a little time up front, but it saves years of trouble down the road.

Chris Battaini Roofing and Seamless Gutters services Berkshire, Hampden, Hampshire, and Franklin Counties in Massachusetts.

The Foundation: Batten vs. Direct-to-Deck Installation

Choosing an installation method affects appearance, energy performance, and cost. Here are the essentials you need to know.

Direct-to-Deck Method: A Streamlined Approach

- Panels fasten directly to the sheathing over underlayment.

- Lower-profile lookgreat for contemporary designs.

- Fewer materials mean slightly lower costs and quicker installs. See our guide on attaching metal roofing.

Batten System Method: The Air Gap Advantage

- 2×2 or 1×4 battens create an airflow cavity that can cut heat transfer by up to 70%.

- Excellent for leveling minor deck irregularities and reducing ice dams.

- A taller profile mimics traditional shakes or barrel tile without the weight.

How to Properly Install a Batten System

- Snap chalk lines and fasten battens 148 in. on center (139 in. at the eave).

- Drive fasteners into rafters, not just sheathing.

- Keep grids squaresmall errors here cause big headaches later.

Counter-battens (a second layer installed perpendicular to the first) add even more ventilation on low-slope roofs common around the Berkshires.

For help deciding which method fits your home, visit our metal roofing page or call for a site-specific evaluation.

Chris Battaini Roofing and Seamless Gutters services Berkshire, Hampden, Hampshire, and Franklin Counties in Massachusetts.

The Core of Your Stone Coated Steel Roofing Installation

With the foundation ready, we install the panels that will protect your home for decades.

Laying and Fastening the Main Field Panels

- Start bottom-left, work upward and outward.

- Stagger courses for strength and a natural look.

- Follow manufacturer fastening patternscritical for 120 mph wind ratings.

- Minimum slope is 3:12 for weatherproof performance.

Navigating Hips, Valleys, and Ridges

- Valleys: Pre-formed metal flashing channels water; panels are cut and tucked for a clean finish.

- Hips & Rakes: Panels are bent to hug the angle, then trimmed for crisp edges.

- Ridge Caps: Closure strips and sealant lock out wind-driven rain.

Flashing and Sealing Roof Penetrations

- Install full courses below skylights, stacks, or chimneys, then apply custom flashings.

- Only non-acidic silicone or urethane sealant touches the metal.

- Touch-up stone granules hide any exposed edges.

Flashing is where most leaks start on any roof, so we slow down heremeasured cuts, tight fits, generous sealant, done.

For more on problem-solving tricky leaks, see our roof leak repair services.

Chris Battaini Roofing and Seamless Gutters services Berkshire, Hampden, Hampshire, and Franklin Counties in Massachusetts.

Advanced Installations and Finishing Touches

The durability and versatility of a stone coated steel roofing installation extend beyond just basic panel application. Modern roofing often involves integrating additional features like solar panels, and the final touches are just as important for longevity and aesthetics.

How to Install Solar Mounts on a Stone Coated Steel Roof

Integrating solar panels onto a stone coated steel roof might seem challenging, but with the right techniques, it’s surprisingly efficient and can often be done without penetrating or removing the actual roofing panels. This is a significant advantage for preserving your roof’s integrity.

Our process involves:

- Locating Rafters: We accurately locate the roof rafters, which are the structural members that can support the weight of the solar array. This is crucial for secure mounting.

- Unfastening and Lifting Panels: Instead of removing panels entirely, we carefully unfasten the bottom nose of overlapping panels and gently lift them. Stone coated steel panels are surprisingly flexible, allowing us to create enough workspace. We often use a prybar wedge to hold the lifted panels, preventing damage and maintaining space for drilling.

- Sealing Pilot Holes: Once the rafters are located and pilot holes are predrilled for the mounting hardware, we apply sealant (like a non-acidic silicone or urethane) into these holes. This extra measure protects the underlayment and ensures a watertight seal around the mounting screws.

- Securing Mounts: We then drive mounting screws to secure the solar mounts directly into the rafters.

- Lowering and Refastening: After the mounts are securely in place, we carefully lower the stone coated steel panels back into their original position and refasten them, ensuring they interlock perfectly. The mounts are designed to allow the solar rails to exit between courses without requiring additional flashing, maintaining the roof’s clean lines and weatherproofing.

This method ensures a durable solar array while preserving the integrity and warranty of your stone coated steel roofing installation.

The Final Details: Touch-Ups and Cleanup

Once all the panels are laid and fastened, and all the intricate flashing is complete, we turn our attention to the final details. These steps are crucial for both the aesthetic appeal and the long-term performance of your new roof:

- Applying Touch-Up Kits: During installation, minor scuffs or scratches can occur on the stone coating. We use manufacturer-provided touch-up kits, which include matching stone granules and an adhesive, to repair these areas. This ensures a uniform appearance and protects the underlying steel.

- Sealing Exposed Fasteners: Any exposed fastener heads, particularly at the ridge or around custom flashings, are sealed with a dab of matching touch-up coating or high-quality sealant. This provides an extra layer of weather protection and blends the fasteners seamlessly into the roof.

- Thorough Cleanup: This is a step we take very seriously. All metal shavings, debris, and discarded materials are carefully collected and removed from the roof and surrounding property. Metal shavings, if left on the roof, can rust and stain the panels, compromising the aesthetic appeal of your beautiful new stone coated steel roofing installation.

A final, comprehensive inspection is performed to ensure every detail meets our high standards of quality and workmanship.

Post-Installation Care and Your Stone Coated Steel Roofing Installation Warranty

One of the most appealing aspects of stone coated steel roofing is its impressive longevity, with manufacturers offering warranties that can last 50 years or more. While these roofs are incredibly durable and low-maintenance, a little post-installation care can go a long way in maximizing their lifespan and ensuring your warranty remains valid.

We recommend simple maintenance tips, primarily an annual professional inspection. This allows us to identify and address any minor issues, such as debris accumulation or sealant degradation, before they become significant problems. While you can walk on a stone coated steel roof, it’s best left to trained professionals to avoid damage to the panels or injury to yourself.

Understanding your manufacturer’s warranty is also vital. These warranties typically cover defects in materials and performance for decades, often including hail damage coverage. However, these warranties are often contingent on professional installation. This is why choosing a reputable and experienced contractor like Chris Battaini Roofing and Seamless Gutters is so important. Our owner-led, on-site service and exceptional workmanship warranties ensure that your stone coated steel roofing installation is not only done correctly the first time but also fully compliant with manufacturer requirements, protecting your investment for generations.

Frequently Asked Questions about Stone Coated Steel Roof Installation

When homeowners in Berkshire County are considering a stone coated steel roofing installation, we hear the same questions over and over. Let’s tackle the big ones that keep coming up during our consultations.

How long does a stone coated steel roof installation take?

The honest answer? It depends entirely on what we’re working with. Every roof tells its own story, and some are definitely more complicated than others.

For a simple, walkable roof without too many bells and whistles, our experienced crews can really move. We’re talking about installing up to 20 squares (that’s 2,000 square feet) in a single day when everything goes smoothly. These are typically single-story homes with straightforward layouts and minimal penetrations.

But here’s where it gets interesting – throw in some complexity, and everything changes. A steep, two-story home with multiple skylights, dormers, valleys, and chimneys? That’s a whole different ballgame. We might only complete 3-4 squares per day because every cut needs to be perfect, every piece of flashing needs to be custom-fitted, and safety becomes even more critical on steep slopes.

As a general rule of thumb, a skilled two-person crew can install about one square per hour under normal conditions. But remember, “normal” varies wildly from house to house. Your stone coated steel roofing installation timeline will depend on your specific roof’s personality.

Is a stone coated steel roof noisy in the rain?

This might be the biggest myth about metal roofing, and we love busting it! People picture themselves lying awake during thunderstorms, listening to what sounds like a drum solo on their roof. The reality is refreshingly different.

A properly installed stone coated steel roofing installation is actually remarkably quiet. Think about all the layers working together: the stone coating itself acts as a sound dampener, the underlayment provides another buffer, and if you’ve got a batten system, that air gap works like acoustic insulation. Add in your attic space and insulation below, and you’ve got a pretty impressive sound barrier.

Most of our customers are genuinely surprised by how quiet their new roof is during rain. In fact, many tell us it’s actually quieter than their old asphalt shingles were. Now, if we get hit with tennis ball-sized hail (which these roofs can handle beautifully), you might hear something. But your everyday rainstorm? You’ll sleep like a baby.

Can you install stone coated steel over existing shingles?

This is where we need to have an honest conversation about what’s best for your home versus what’s simply possible. Technically, yes, sometimes we can install stone coated steel panels over existing asphalt shingles. Local building codes might allow it, and if your existing roof is in excellent condition with just one layer of shingles, it could work.

There are even some potential benefits to leaving the old shingles in place. They can provide extra insulation and sound dampening, plus you’ll save on disposal costs and the mess of a full tear-off.

But here’s our professional recommendation: for the best performance and longevity of your stone coated steel roofing installation, we almost always suggest a complete tear-off. Why? Because we want to see what’s underneath. Hidden damage, compromised sheathing, or structural issues can’t be properly addressed if we’re working over the old roof.

Starting with a clean, flat surface gives us the best foundation for your new roof. It ensures proper drainage, allows us to inspect and repair any deck issues, and gives you the peace of mind that comes with knowing your investment is built on solid ground. Every situation is unique, though, so we’ll always assess your specific roof and recommend the approach that makes the most sense for your home and budget.

Conclusion: Your New Roof Awaits

When you choose stone coated steel roofing installation, you’re not just getting a new roof—you’re making a once-in-a-lifetime investment in your home’s future. This remarkable roofing system delivers something truly special: the perfect marriage of durability that lasts 50+ years, aesthetic beauty that rivals traditional materials, and weather resistance that stands up to whatever Mother Nature throws your way.

Throughout this comprehensive guide, we’ve walked you through every crucial step of the installation process. From the initial roof deck preparation and underlayment installation to the precise panel laying techniques and intricate flashing work around complex roof features, each phase requires expertise, attention to detail, and professional-grade tools. This isn’t a weekend DIY project—it’s a sophisticated installation that demands the skills of experienced professionals.

The difference between a good roof and a great roof often comes down to the quality of installation. Even the finest stone coated steel panels won’t perform to their full potential without proper installation techniques. That’s where the batten system spacing, correct fastening patterns, and meticulous flashing work we’ve discussed become absolutely critical to your roof’s long-term success.

For homeowners throughout Berkshire County and Southern Vermont, partnering with Chris Battaini Roofing and Seamless Gutters means you’re working with professionals who understand these systems inside and out. Our owner-led, on-site service ensures that Chris himself oversees your project, bringing decades of experience to every installation. We don’t just install roofs—we craft protective systems that safeguard your most important investment.

Our exceptional workmanship warranties provide additional peace of mind, complementing the manufacturer’s impressive guarantees. When you combine professional installation with quality materials, you get a roof that truly delivers on its promise of decades of reliable performance.

Ready to transform your home with a roof that combines timeless beauty with best durability? Your new stone coated steel roofing installation awaits, and we’re here to make it happen. Get in touch with our experts to discuss your metal roofing project today—let’s build something that will protect your family for generations to come.

Chris Battaini Roofing and Seamless Gutters services Berkshire, Hampden, Hampshire, and Franklin Counties in Massachusetts.