Why Understanding Your Flat Roof Options Matters for Massachusetts Property Owners

Types of flat roofs vary significantly in materials, performance, and cost, making the right choice crucial for your property’s long-term protection and value. Whether you’re considering a new installation or replacement, understanding these options helps you make an informed decision that fits your budget and climate needs.

Quick Answer: Main Types of Flat Roofs

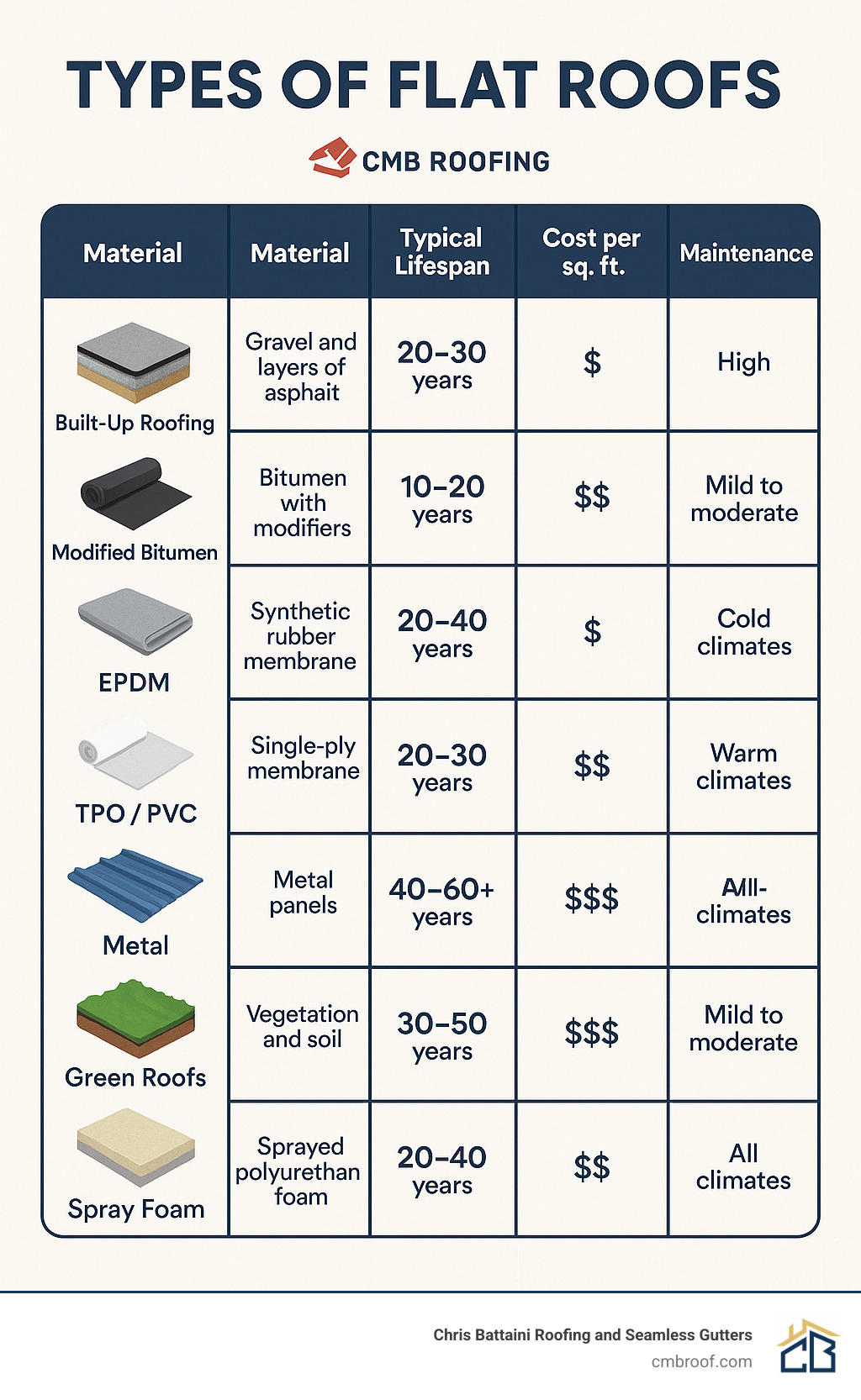

– Built-Up Roofing (BUR) – Traditional hot-mop system with gravel surfacing (20-30 years)

– Modified Bitumen – Flexible rubber/plastic sheets, torch-down or peel-and-stick (10-20 years)

– EPDM Rubber – Synthetic rubber membrane, most popular commercial option (20-50 years)

– TPO/PVC Single-Ply – Heat-welded white membranes for energy efficiency (20-30 years)

– Metal Panels – Standing seam systems for longevity (50+ years)

– Green Roofs – Living vegetation systems for eco-friendly performance (30-40 years)

– Spray Foam (SPF) – Seamless insulation and waterproofing layer (20-50 years)

Flat roofs aren’t actually flat – they have slopes of less than 10 degrees to allow proper drainage. This low profile offers unique advantages like usable rooftop space and lower installation costs compared to steep-slope roofing.

In Massachusetts, flat roofs face specific challenges from freeze-thaw cycles, heavy snow loads, and temperature swings. The right material choice depends on your building’s use, budget, and local weather patterns. Some systems excel in our climate while others may struggle with thermal expansion or ice damage.

From traditional built-up systems that have protected buildings for over a century to modern single-ply membranes offering superior energy efficiency, each flat roof type brings distinct advantages and trade-offs.

Find more about types of flat roofs:

– flat roofing

– flat roofing materials

Flat vs Pitched Roof Basics

Think you know the difference between flat and pitched roofs? There’s more to it than meets the eye, and understanding these fundamentals will help you make the best choice for your property.

Flat roofs aren’t actually flat – they maintain slopes between 1/4 inch and 3 inches per foot (that’s roughly 1% to 25% grade). Building codes require this minimum 1/4 inch per foot slope to prevent water from pooling like a backyard pond after a rainstorm. Compare this to pitched roofs that typically start at 3 inches per foot and can go much steeper.

This slope difference creates a completely different approach to water management. Pitched roofs rely on speed – water hits those steep shingles and races toward the gutters like kids on a waterslide. Flat roofs take their time – water moves slowly across a continuous membrane surface toward strategically placed drains, scuppers, or edge gutters.

The structural load considerations tell an interesting story too. While pitched roofs shed snow naturally, flat roofs in our Massachusetts climate must handle significant snow accumulation. Here in Berkshire County, we’ve seen snow loads exceed 50 pounds per square foot – that’s like having a small car parked on every 10×10 section of roof.

But here’s where types of flat roofs really shine: usable rooftop space. Try installing solar panels or HVAC equipment on a steep pitch – you’ll quickly appreciate the convenience of a flat, walkable surface. Many property owners find their roof becomes valuable real estate for equipment, gardens, or even outdoor gathering spaces.

The aesthetic appeal of flat roofs complements modern architectural styles beautifully. Those clean, horizontal lines create a sleek profile that pitched roofs simply can’t match. Plus, first-cost savings make flat roofs attractive – simpler framing, reduced material quantities, and easier installation often mean lower upfront investment.

Maintenance access becomes a breeze with flat roofs. Instead of tiptoeing across steep shingles, you can walk safely across the surface for inspections and repairs. This accessibility often translates to better long-term care and fewer surprise problems.

Anatomy & Drainage Essentials

Think of a flat roof like a layered cake – each component has a specific job, and they all need to work together perfectly. When one layer fails, the whole system can suffer. Let’s break down what makes these types of flat roofs actually work.

The structural deck forms your foundation – usually plywood, OSB, or concrete that carries all the weight above. For homes in our area, we typically use 18mm minimum thickness OSB3 or plywood over timber joists that are sized to handle those hefty Massachusetts snow loads. Nobody wants their roof sagging under three feet of February snow.

Moving upward, the vapor control layer acts like a one-way ticket for moisture. It prevents humid air from your heated home from sneaking up into the insulation where it could condense and cause real problems. This barrier always goes on the warm side of the insulation – a detail that can make or break your roof’s performance.

Insulation keeps your energy bills reasonable and meets strict Massachusetts building codes. New construction must hit U-values of 0.11 W/m²K, while roof upgrades need 0.15 W/m²K. These numbers might sound technical, but they translate to real comfort and savings.

The weatherproofing membrane is where the magic happens – this critical layer defines what type of flat roof system you have. Whether it’s built-up roofing, EPDM rubber, or TPO single-ply, this membrane keeps water where it belongs: outside your building.

Finally, surfacing materials protect that expensive membrane from UV rays, foot traffic, and weather damage. Options range from traditional gravel ballast to modern reflective coatings or integrated cap sheets.

Here’s where many flat roofs succeed or fail: drainage design. Water that sits too long will eventually find its way through even the best membrane. We create positive drainage through several proven methods.

Tapered insulation gradually increases thickness to create slopes without messing with your interior ceiling heights. This approach works beautifully for retrofit projects where you can’t change the structural deck.

Internal drains positioned at low points collect water efficiently, but they require careful detailing around penetrations. One poorly sealed drain can cause thousands in damage.

Scuppers and overflow drains provide backup drainage when leaves or debris block primary drains. Think of them as insurance against catastrophic ponding – because autumn in Massachusetts means lots of falling leaves.

The choice between warm and cold roof assemblies affects both performance and installation complexity. Warm roofs place insulation above the structural deck, keeping everything at comfortable temperatures and eliminating condensation risks. Cold roofs put insulation below the deck but require ventilation and vapor control – we rarely use them today because they’re complex and prone to problems.

Types of Flat Roofs: Materials, Pros & Cons

Choosing the right flat roof material can feel overwhelming with so many options available today. Each system has evolved to solve specific problems, whether that’s extreme weather resistance, energy efficiency, or budget constraints. Understanding how these types of flat roofs compare helps you make a smart decision for your property.

The cost and performance differences between materials are significant. Built-up roofing might cost $4-$12 per square foot and last 20-30 years, while premium metal systems can run $8-$24 per square foot but protect your building for 50+ years. The math isn’t always straightforward – sometimes spending more upfront saves money over the roof’s lifetime.

Here’s how the major types of flat roofs stack up in our Massachusetts climate:

| Material | Cost Range (per sq ft)* | Typical Lifespan | Best Applications |

|---|---|---|---|

| Built-Up (BUR) | $4-$12 | 20-30 years | Heavy foot traffic areas |

| Modified Bitumen | $6-$18 | 10-20 years | Cold climates, moderate budgets |

| EPDM Rubber | $3-$15 | 20-50 years | Commercial buildings |

| TPO/PVC | $4-$14 | 20-30 years | Energy efficiency priorities |

| Metal Panels | $8-$24 | 50+ years | Longevity, aesthetics |

| Green Roofs | $15-$50 | 30-40 years | Environmental goals |

| Spray Foam | $4-$16 | 20-50 years | Retrofit applications |

*Average costs based on internet data, not actual costs for Chris Battaini Roofing and Seamless Gutters

The wide price ranges reflect real-world variables like material quality, installation complexity, and regional labor costs. A basic EPDM installation might hit the lower end, while a fully adhered premium membrane with extensive detailing reaches the higher costs.

Our Massachusetts weather throws everything at flat roofs – from below-zero winters to 90°F summers, plus heavy snow loads and those brutal freeze-thaw cycles. Some materials handle this punishment better than others. EPDM rubber stays flexible in cold weather, while modified bitumen can crack if it’s not formulated properly for our climate.

The key is matching the material to your specific situation. A warehouse roof that nobody walks on has different needs than a residential flat roof where you’ll be accessing HVAC equipment regularly. Similarly, a building owner planning to sell in five years might choose differently than someone planning to stay put for decades.

Built-Up Roofing (BUR): Classic Foundation of Types of Flat Roofs

Built-up roofing has protected buildings for over a century, and there’s a reason it’s still around. This time-tested approach creates a waterproof membrane by layering asphalt-impregnated felt with hot bitumen, building up thickness one ply at a time.

The installation process looks almost medieval – workers heat asphalt in kettles and mop it between layers of reinforcing felt. Each layer overlaps the previous one, creating a 2-4 ply membrane that gets thicker and stronger with each pass. The final touch is usually gravel or mineral granules that protect against UV rays and foot traffic.

BUR systems excel in several key areas that matter for Massachusetts properties. The multiple redundant layers mean if one gets damaged, you’ve got backup protection underneath. The aggregate surfacing handles our harsh winters beautifully, resisting ice damage and thermal stress that can crack other materials.

We’ve seen BUR roofs last 20-30 years with proper maintenance, and they’re nearly indestructible under foot traffic. If you’ve got rooftop HVAC equipment that needs regular service, BUR won’t complain about technicians walking around with tools and parts.

The cost effectiveness is hard to beat too, typically running $4-$10 per square foot installed. For building owners who need proven performance without premium pricing, BUR delivers solid value.

The downsides are real though. The hot asphalt application creates fumes and safety concerns that require experienced crews. Installation depends heavily on weather – you need dry conditions and moderate temperatures. The finished roof is also quite heavy, which might require structural reinforcement on older buildings.

BUR works particularly well in our climate because it handles freeze-thaw cycles without missing a beat. Those multiple layers and gravel protection provide excellent defense against ice damage that can destroy thinner membrane systems.

Modified Bitumen Systems

Modified bitumen bridges the gap between traditional BUR and modern single-ply membranes by adding rubber or plastic polymers to asphalt. This creates a more flexible, durable material that still feels familiar to contractors experienced with asphalt systems.

The two main polymer types offer different strengths. SBS (Styrene-Butadiene-Styrene) adds rubber-like flexibility that’s perfect for cold climates like ours. APP (Atactic Polypropylene) provides plastic-like properties with excellent UV resistance for sunny exposures.

Installation methods vary from torch-down application that creates strong adhesion, to cold adhesive systems and self-adhering membranes that eliminate fire safety concerns. Torch-down remains popular because it creates such a strong bond, though it requires skilled technicians who understand fire safety protocols.

Modified bitumen shines in Massachusetts winters because the polymer modification keeps it flexible when other materials get brittle. The reflective cap sheet options help with energy efficiency during our hot summers, while the moderate cost of $6-$15 per square foot fits many budgets.

The trade-offs include limited scuff resistance that makes it unsuitable for heavy foot traffic, and a shorter lifespan of 10-20 years compared to premium systems. Seam vulnerability requires careful installation and ongoing maintenance attention.

We’ve had good success with SBS formulations that maintain flexibility even when temperatures drop well below freezing. The reflective granule surfacing available on many products helps reduce cooling loads during those humid July and August heat waves.

EPDM Rubber Membrane

EPDM dominates commercial flat roofing for good reason – it’s tough, reliable, and relatively simple to install. This synthetic rubber membrane accounts for about 40% of single-ply installations nationwide, with many roofs lasting well beyond their expected lifespan.

The material itself is impressive. EPDM sheets come in thicknesses from 45 to 90 mils and widths up to 50 feet, allowing large areas to be covered with minimal seams. It stays flexible from -40°F to 300°F without degradation, resists UV damage, and shrugs off chemical exposure that would destroy other materials.

Installation flexibility makes EPDM adaptable to different situations. Fully adhered systems bond to the substrate with adhesive for maximum wind resistance. Mechanically attached systems fasten through the membrane at seams and perimeter. Ballasted systems use gravel or pavers to hold everything in place, which works well in low-wind areas.

EPDM’s exceptional longevity sets it apart from other options. We’ve seen documented lifespans of 20-50 years, with some installations still performing well after five decades. The simple installation reduces labor costs and installation time compared to multi-ply systems.

The material is also 100% recyclable, which appeals to environmentally conscious building owners. Installation doesn’t require hot asphalt or torch application, making it safer and more weather-friendly than some alternatives.

EPDM considerations include the traditional black surface that absorbs heat and potentially increases cooling costs. Seam dependency means most failures occur at joints rather than in the membrane itself. The material can be punctured by sharp objects, so protection during and after installation matters.

Thermoset EPDM roofing membranes have evolved to include white formulations and peel-and-stick installation systems that simplify application. The material’s flexibility makes it excellent for our climate where thermal movement is significant.

TPO & PVC Single-Ply Options

Thermoplastic single-ply membranes represent the newest generation of flat roofing technology, with TPO becoming increasingly common for new commercial installations. These materials create heat-welded seams that form monolithic waterproof surfaces stronger than the membrane itself.

TPO (Thermoplastic Polyolefin) offers several compelling features. The white reflective surface can reduce cooling loads by 10-15%, which adds up to real savings during our humid summers. Chemical resistance to oils, fats, and many industrial chemicals makes it suitable for restaurants and manufacturing facilities.

PVC membranes bring their own advantages, including inherent fire resistance that meets strict building codes and superior weldability that creates reliable seam performance. Some PVC installations have exceeded 30 years of service life, proving the technology’s long-term viability.

Both materials come in thicknesses from 45 to 80 mils, with thicker membranes providing better puncture resistance and longevity. The white reflective surfaces can significantly reduce summer cooling costs compared to black EPDM or dark BUR systems.

Single-ply advantages include fast installation with large sheet sizes and mechanical attachment options, lightweight construction that reduces structural load requirements, and energy efficiency from reflective surfaces that meet cool roof standards.

Potential challenges include puncture sensitivity that requires careful installation and maintenance, thermal movement that can stress seams and attachments, and quality variations between manufacturers that affect long-term performance.

TPO roofing has gained popularity due to its energy efficiency and competitive pricing. However, early TPO formulations experienced premature failures, making manufacturer selection and installation quality critical factors for success.

Metal Panels (Low-Slope)

Metal roofing systems adapted for low-slope applications offer best longevity and sustainability, though at higher initial costs. Standing seam systems work effectively on slopes as low as 2:12 (about 9.5 degrees) with proper detailing and installation techniques.

Common metal options include steel with various coating systems for corrosion protection, aluminum offering natural corrosion resistance and light weight, copper providing premium aesthetics and 100+ year lifespans, and zinc combining durability with self-healing patina formation.

Metal roofing advantages are impressive. Exceptional longevity with 50+ year lifespans is common, fire resistance meets the highest building code requirements, and 100% recyclability supports sustainable building practices. Color variety in dozens of standard and custom options plus superior hail resistance compared to membrane systems round out the benefits.

Metal system considerations include higher initial costs ranging $8-$24 per square foot installed, thermal movement requiring expansion joint details, condensation potential needing proper vapor control design, and noise considerations during rain and hail events.

Metal systems work well in our climate zone, handling snow loads effectively and resisting ice damage that can destroy other materials. The key lies in proper slope design and thermal movement accommodation through clip systems and expansion joints.

Green & Living Roofs: Eco-Friendly Types of Flat Roofs

Green roofing systems transform flat roofs into living ecosystems that provide environmental benefits while protecting the building envelope. These systems range from simple sedum mats to complex garden installations supporting diverse plant communities.

Green roof components work together as a complete system. The waterproof membrane (typically EPDM or modified bitumen) provides the foundation, while a root barrier prevents plant damage to the roofing system. A drainage layer manages excess water while retaining moisture, growing medium specially formulated for roof applications supports plant growth, and vegetation selected for local climate and maintenance requirements completes the system.

Environmental benefits are substantial. Stormwater management can reduce runoff by 50-90%, urban heat island mitigation cools surrounding air temperatures, and energy efficiency comes from natural insulation and evapotranspiration cooling. Air quality improvement through filtering pollutants and producing oxygen, plus wildlife habitat supporting birds, insects, and urban biodiversity add to the appeal.

Green roof advantages include extended membrane life of 30-40 years due to protection from UV and temperature extremes, sound insulation reducing noise transmission, fire resistance from moisture content and mineral growing medium, and property value improvement through unique amenity and environmental benefits.

Implementation challenges are significant though. High initial costs ranging $15-$50 per square foot, structural requirements for 80-150 pounds per square foot loads, maintenance needs including irrigation, fertilization, and plant care, and professional design required for plant selection and system integration all require careful consideration.

Green roofs work well in Massachusetts climate with proper plant selection. Sedum varieties and native grasses provide low-maintenance options that survive our temperature extremes and precipitation patterns.

Spray Polyurethane Foam & Liquid-Applied Systems

Spray polyurethane foam (SPF) and liquid-applied membranes create seamless roofing systems that conform to any roof shape while providing both insulation and waterproofing. These systems excel in retrofit applications where existing roof removal would be costly or disruptive.

SPF systems combine polyurethane foam sprayed in multiple lifts to desired thickness, protective coating providing UV protection and waterproofing, and optional granule surfacing for improved durability and aesthetics. Liquid-applied options include silicone coatings offering excellent UV resistance and flexibility, acrylic systems providing cost-effective restoration solutions, and polyurethane membranes delivering superior durability and chemical resistance.

Seamless system advantages are compelling. No seams or fasteners eliminate common failure points, self-flashing capability around penetrations and details simplifies installation, and high insulation value with R-6 to R-8 per inch of foam thickness improves energy efficiency. Lightweight construction adds minimal structural load, while renewable surfaces through recoating cycles can extend life to 20-50 years.

Application considerations include weather-sensitive installation requiring dry conditions and moderate temperatures, quality control challenges dependent on applicator skill and equipment, thickness variations potentially affecting performance and warranties, and specialized contractors limiting availability and competition.

SPF systems work particularly well for recovering existing flat roofs where removal costs would be prohibitive. The seamless nature eliminates leak-prone seams while adding significant insulation value – a win-win for building performance and owner budgets.

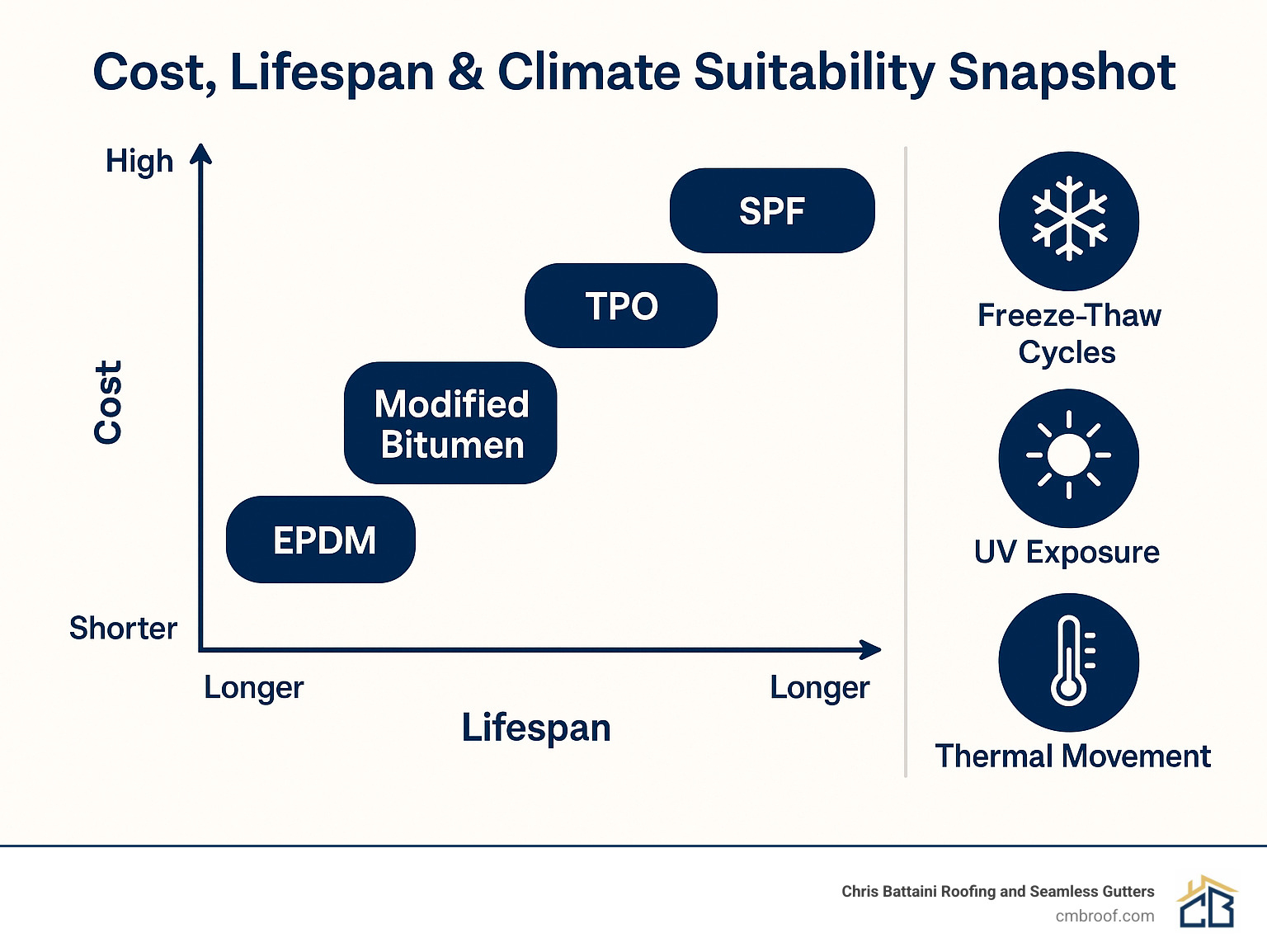

Cost, Lifespan & Climate Suitability Snapshot

When you’re choosing between types of flat roofs, the real-world performance in our Massachusetts climate often matters more than the sticker price. After decades of installing and maintaining these systems across Berkshire County, we’ve seen how different materials handle our unique weather challenges.

Our brutal freeze-thaw cycles separate the winners from the wannabes. When temperatures swing from -20°F in January to 95°F in July, materials expand and contract dramatically. Modified bitumen and EPDM rubber handle this stress beautifully, staying flexible when other materials crack. Some early TPO formulations struggled with these temperature swings, though newer versions perform much better.

Snow loads present another reality check for flat roof materials. We regularly see snow loads exceeding 50 pounds per square foot, and that’s just the beginning. Add ice dams and you’re looking at serious structural stress. Metal systems laugh at these loads, while membrane systems depend entirely on proper structural support underneath.

The high UV exposure at our elevation, amplified by reflective snow cover, beats up roofing materials year-round. White TPO and PVC membranes reflect this punishment back into space, while granule-surfaced materials provide excellent protection. Traditional black EPDM absorbs heat like crazy, which can drive up cooling costs in summer.

Regional labor costs create significant pricing variations across our service area. Rural locations often mean limited contractor availability, while material transportation adds unexpected expenses. We’ve watched project costs swing 30-50% based purely on location and timing – it’s not just about the materials themselves.

The maintenance reality varies dramatically between systems. BUR and modified bitumen need annual inspections and recoating every 5-7 years. EPDM systems require bi-annual check-ups with occasional seam maintenance. TPO and PVC follow similar schedules but focus more on seam repairs. Metal roofs need annual inspections but can go 15-20 years between coating renewals. Green roofs demand monthly attention during growing season plus annual system inspections. SPF systems need yearly check-ups and recoating every 10-15 years.

Smart buyers look beyond initial costs to total lifecycle value. A premium metal system might cost twice as much upfront but deliver three times the lifespan with minimal maintenance. Meanwhile, a budget modified bitumen installation could need replacement just as you’re hitting your stride with equipment installations or landscaping investments.

The thermal movement challenge affects every flat roof system differently. Our temperature extremes create massive expansion and contraction forces. Flexible membranes like EPDM roll with these changes, while properly detailed metal systems accommodate movement through engineered clip systems and expansion joints. Rigid materials without proper accommodation details often fail prematurely.

More info about Flat Roofing Materials

Maintenance, Common Issues & Myths Debunked

Taking care of your flat roof doesn’t have to be complicated, but it does require regular attention. Think of it like maintaining your car – a little preventive care goes a long way toward avoiding expensive surprises down the road.

We recommend semi-annual inspections in spring and fall, plus a quick check after any severe weather. These routine visits help catch small problems before they become major headaches.

Debris removal tops the priority list for flat roof maintenance. Leaves, branches, and other organic matter don’t just make your roof look messy – they trap moisture against the membrane and can block critical drainage. We’ve seen expensive damage from something as simple as a clogged drain that could have been cleared with a few minutes of attention.

Speaking of drainage, checking drains and scuppers should be part of every inspection. When these get blocked, water has nowhere to go except to pool on your roof. That standing water weighs about 5 pounds per square foot per inch of depth – more load than most roofs were designed to handle permanently.

Seam and flashing inspection reveals where most flat roof problems actually start. Despite what people think, flat roofs rarely fail in the middle of a membrane. Instead, leaks develop at joints, around penetrations, and where different materials meet. A small separation caught early might need just a dab of sealant, while the same problem ignored for months could require major repairs.

The membrane surface itself needs attention too. Look for punctures from falling branches, tears from foot traffic, or blisters that indicate moisture problems underneath. Single-ply membranes like TPO and EPDM are particularly vulnerable to sharp objects, so protection during maintenance work is essential.

Ponding water deserves special mention because it’s both a symptom and a cause of problems. Water that stands longer than 48 hours after rain indicates drainage issues that need correction. This might be as simple as clearing a blocked drain or as complex as adding tapered insulation to improve slope.

Let’s clear up some persistent myths about types of flat roofs that we hear regularly:

The biggest myth claims that “flat roofs always leak.” This simply isn’t true with modern materials and proper installation. We’ve maintained flat roofs that haven’t leaked in decades. Most leak problems trace back to poor installation, inadequate maintenance, or trying to save money with inferior materials.

Another common misconception suggests that “flat roofs don’t drain properly.” Modern flat roof design includes positive drainage through minimum slopes, tapered insulation systems, and multiple drain paths. Building codes require these features specifically to ensure water removal.

Some property owners believe “flat roofs cost more to maintain” than pitched systems. While the maintenance tasks differ, total costs often compare favorably when you consider the easier access and ability to spot problems before they cause interior damage.

Perhaps the most dangerous myth claims that “all flat roofing materials perform the same.” As we’ve covered throughout this guide, significant differences exist between BUR, single-ply membranes, metal systems, and other options. Choosing the wrong material for your climate or application can lead to premature failure and expensive replacement.

Professional installation versus DIY becomes a critical decision point for many property owners. While we appreciate the satisfaction of hands-on work, flat roofing presents unique challenges that make professional installation almost always the better choice.

Safety concerns top the list – flat surfaces can be surprisingly slippery, especially when wet, and the low parapets provide minimal fall protection. Specialized tools for heat welding seams, applying hot asphalt, or spraying foam require training and experience to use safely and effectively.

Warranty considerations often make DIY installation a false economy. Most manufacturer warranties require professional installation by certified contractors. A DIY job might save money upfront but void warranty protection that could cover expensive repairs later.

Code compliance adds another layer of complexity. Proper permits, inspections, and adherence to local building codes require knowledge that most DIY enthusiasts don’t possess. Getting it wrong can create problems when selling the property or filing insurance claims.

Small repairs like cleaning drains or applying emergency patches might be suitable for handy property owners, but major work should involve qualified professionals. We’ve seen too many cases where fixing DIY mistakes cost more than professional installation would have in the first place.

Research from the Scientific research on urban heat island effect shows how reflective roofing materials reduce cooling energy use by 10-15% while decreasing urban air temperatures. This demonstrates how proper material selection affects both your energy bills and the broader environment.

Regular maintenance protects your investment while supporting these environmental benefits. A well-maintained reflective roof continues performing efficiently for decades, while a neglected system loses effectiveness and requires premature replacement.

More info about Commercial Roof Repair Solutions

Frequently Asked Questions about Choosing a Flat Roof

What flat roof type offers the longest service life?

When homeowners ask about longevity, metal panel systems consistently win the durability contest. These standing seam steel or aluminum roofs often cruise past the 50-year mark, with some installations lasting 30-70 years depending on coating systems and how well they’re maintained.

Here’s what makes metal so impressive: it handles our Massachusetts weather like a champ. Snow loads that might stress membrane systems barely register on properly installed metal roofing. The material doesn’t degrade from UV exposure the way some membranes can, and it’s practically immune to puncture damage from falling branches.

SPF (spray polyurethane foam) systems offer a clever alternative approach to longevity. While the base system might last 20-30 years, the renewable coating cycles can extend total life to 50+ years. Think of it like repainting your house – you’re refreshing the protective layer without replacing the entire system.

Among membrane types of flat roofs, EPDM rubber takes the longevity crown. We’ve seen installations pushing 40-50 years with proper care. The synthetic rubber stays flexible even when temperatures swing from below zero to scorching summer heat, and it shrugs off UV damage that can shorten other materials’ lives.

But here’s the thing about “longest lasting” – it doesn’t always equal “best value.” A 20-year TPO system might cost half what a premium metal roof costs upfront. Sometimes replacing a roof twice over 40 years costs less than installing the premium option once, especially when you factor in improved technology that becomes available over time.

How do flat roofs drain effectively without pooling?

The secret to effective flat roof drainage lies in understanding that “flat” roofs aren’t actually flat – they’re carefully engineered to move water exactly where it needs to go. Building codes require at least 1% slope (about 1/8 inch per foot), but we typically design for 1/4 inch per foot to account for real-world construction tolerances.

Tapered insulation systems provide the most neat solution for creating proper drainage. Instead of sloping the entire roof structure, we vary the insulation thickness from thin at drains to thick at high points. This creates positive drainage while maintaining level ceiling lines inside your building.

The drainage capacity itself comes from properly sized internal drains designed to handle our local rainfall intensity. We size these systems for 100-year storm events – basically the worst weather we might see in a century. Primary drains handle normal rainfall, while overflow drains positioned 2 inches higher provide backup protection.

Scuppers and overflow systems prevent the catastrophic ponding that can overload your roof structure. Think of them as pressure relief valves – if the main drains get blocked by leaves or debris, water flows out through these secondary systems instead of accumulating to dangerous levels.

The key to long-term success? Regular maintenance keeps drains clear and functioning. Most flat roof water problems we see result from blocked drains rather than system design flaws. A simple twice-yearly cleaning prevents most drainage headaches.

Can homeowners DIY a flat roof installation or should pros handle it?

We get this question a lot, and while we appreciate the DIY spirit, flat roofing really needs professional installation. It’s not just about protecting our business – it’s about protecting you from some serious safety and financial risks.

Safety concerns top our list of worries about DIY flat roofing. Unlike pitched roofs where the edge is obvious, flat roofs can fool you into thinking you’re safely away from the edge when you’re actually in danger. Add hot asphalt, chemical fumes, or torch flames to the mix, and you’re looking at potential disaster.

The technical requirements go way beyond what most homeowners expect. Membrane welding requires specific temperatures and techniques that take years to master. Weather conditions affect installation windows – apply TPO in the wrong temperature or humidity, and the seams might fail within months.

Here’s the financial reality: manufacturer warranties typically require certified installer participation. Install it yourself, and you’ve just voided the warranty on materials that might cost $10,000 or more. When something goes wrong – and flat roofing mistakes usually do go wrong – you’re paying for both the fix and the original materials.

Code compliance adds another layer of complexity. Building permits, structural calculations for snow loads, and inspection requirements vary by location. Professional contractors handle these details as part of their service, ensuring your roof meets all local requirements.

Small repair patches using peel-and-stick materials might work for handy homeowners tackling minor issues. But complete system installation? The cost difference between DIY and professional work often disappears when you factor in tool rental, material waste, and the high probability of expensive mistakes.

Trust us – we’ve fixed enough DIY flat roofing attempts to know that calling professionals first usually costs less than calling them second.

Conclusion

Making the right choice among types of flat roofs isn’t just about picking the cheapest option or the one with the longest warranty. It’s about finding the system that makes sense for your specific building, budget, and long-term goals.

After working on flat roofs throughout Massachusetts for years, we’ve seen how the right material choice can save property owners thousands in energy costs and emergency repairs. We’ve also witnessed the headaches that come from cutting corners or choosing systems that don’t match our local climate.

Climate-smart selection really matters here in New England. Those freeze-thaw cycles that make our roads look like moonscapes? They’re just as tough on roofing materials. Modified bitumen and EPDM rubber handle our temperature swings beautifully, while some early TPO formulations struggled with thermal stress. Metal systems laugh at our weather extremes but require proper expansion joint details to accommodate thermal movement.

The investment in quality materials and professional installation isn’t just about avoiding leaks – though that’s certainly important. It’s about maximizing long-term value through extended service life, predictable maintenance costs, and solid warranty protection. A properly installed EPDM system might cost more upfront than basic built-up roofing, but it often delivers better value over 30+ years when you factor in maintenance and energy savings.

Energy efficiency deserves serious consideration, especially with rising utility costs. White TPO or PVC membranes can cut cooling costs by 10-15% compared to black surfaces. In our climate, that might mean the energy savings pay for the roof upgrade within 15-20 years. Green roof systems take this further, providing natural insulation and managing stormwater runoff that keeps getting more expensive to handle.

Environmental priorities increasingly influence material selection too. Metal roofing offers 100% recyclability at end of life. Green roofs manage stormwater while creating habitat. Even EPDM membranes can be recycled into new products rather than heading to landfills.

As an owner-led operation serving Berkshire, Hampden, Hampshire, and Franklin Counties, we take a different approach than many contractors. When Chris shows up to evaluate your roof, he’s thinking about what system will serve you best for decades – not what generates the highest profit margin this month. That perspective shapes our recommendations and the exceptional workmanship warranties we stand behind.

Professional evaluation considers factors most property owners never think about: structural capacity for snow loads, vapor control requirements, drainage calculations for 100-year storms, and energy code compliance. We’ve seen too many “bargain” installations that turned into expensive problems because these fundamentals got overlooked.

Whether you’re dealing with a leaking commercial building, planning a residential addition, or just trying to understand your options before problems develop, the right flat roof system depends on your unique situation. There’s no one-size-fits-all answer, but there’s definitely a best choice for your specific needs and budget.

More info about Flat Roofing – Contact Chris Battaini Roofing and Seamless Gutters today for a personalized assessment that considers your building’s requirements, local climate challenges, and long-term goals. We’ll help you choose the flat roofing system that delivers the best value and peace of mind for years to come.

Note: All pricing information represents average costs based on internet research and industry data, not specific pricing for Chris Battaini Roofing and Seamless Gutters services.